Precision Manufacturing for Medical Applications

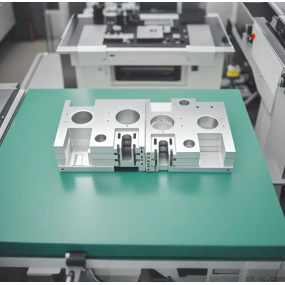

As a leading Manufacturer of CNC-machined medical parts, EMAR specializes in producing high-precision components for medical devices and equipment. Our ISO 13485 certified facility combines advanced CNC technology with strict quality control to meet the demanding requirements of the healthcare industry.

Why Choose EMAR for Medical CNC Machining?

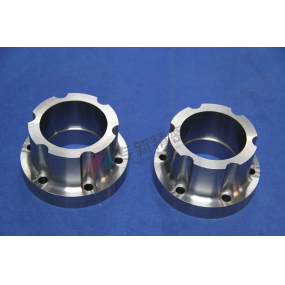

1. Medical-grade materials expertise: We work with biocompatible metals (titanium, stainless steel) and engineering plastics (PEEK, Ultem) compliant with FDA and CE standards.

2. Ultra-precision capabilities: Our 5-axis CNC machines achieve tolerances up to ±.005mm, critical for surgical instruments and implantable devices.

3. Complete validation package: We provide full documentation including material certifications, first article inspection reports, and process validation records.

End-to-End Medical Manufacturing Solutions

From prototyping to mass production, our CNC machining services cover all medical applications including orthopedic implants, dental components, diagnostic equipment parts, and minimally invasive surgical tools. Our cleanroom machining environment ensures contamination-free production for critical medical applications.

Quality Assurance System

EMAR implements a rigorous quality management system featuring CMM inspection, surface roughness testing, and 100% dimensional verification for medical components. Our in-house metrology lab is equipped with advanced measuring instruments to guarantee compliance with your technical specifications.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque