As a leading precision CNC Machining service provider, EMAR delivers exceptional manufacturing solutions for industries requiring micron-level accuracy. Our high-precision CNC machining capabilities combine advanced equipment with technical expertise to meet your most demanding specifications.

What is Precision CNC Machining?

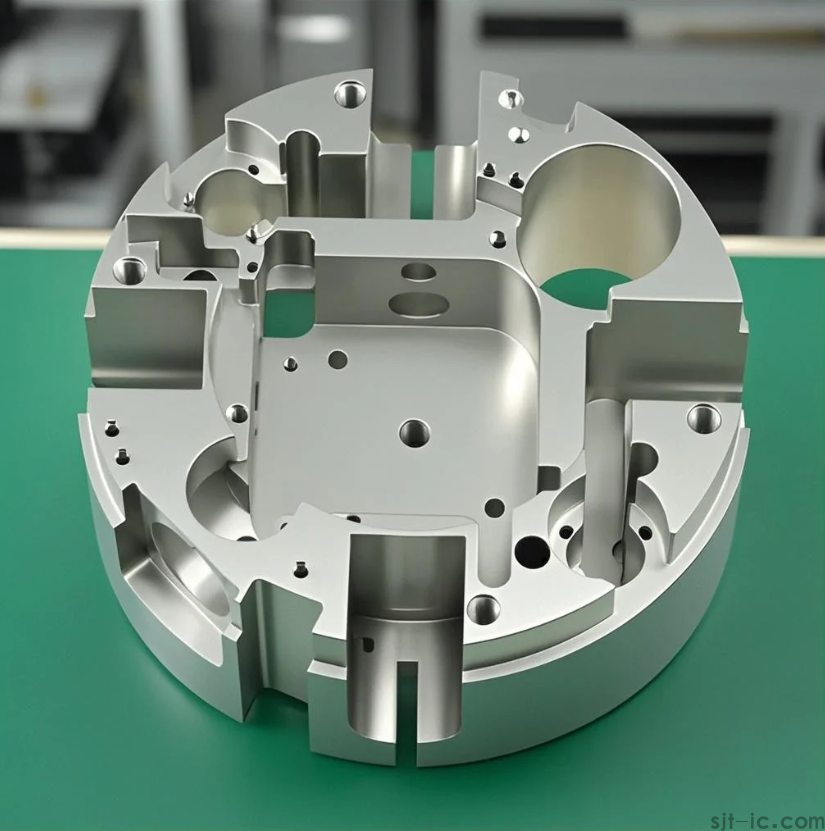

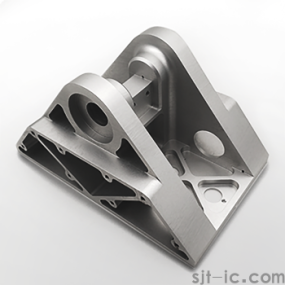

Precision CNC machining refers to the process of manufacturing parts with tolerances typically ranging from ±.001" to ±.0005" (±.025mm to ±.013mm). This level of accuracy is critical for aerospace components, medical devices, optical systems, and other applications where dimensional perfection is non-negotiable.

Our Precision Machining Capabilities

EMAR's facility features state-of-the-art 5-axis CNC machines, Swiss-type lathes, and coordinate measuring machines (CMMs) to ensure:

- Tight tolerances down to ±.0002" (±.005mm)

- Superior surface finishes (Ra 8 µin or better)

- Complex geometries with micron-level consistency

- Material versatility including titanium, Inconel, and engineering plastics

Why Choose EMAR for Your Precision CNC Needs?

1. Technical Expertise: Our AS910-certified team includes engineers with 15+ years of high-precision machining experience

2. Quality Assurance: In-process inspection and final verification with Mitutoyo CMMs

3. Rapid Prototyping: 3-5 day turnaround for precision prototypes

4. Custom Solutions: DFM feedback to optimize your designs for manufacturability

Industries We Serve

• Aerospace & Defense (AS910 compliant)

• Medical & Surgical Devices (ISO 13485 certified)

• Automotive & Motorsports

• Semiconductor Equipment

• Optical & Photonic Systems

Start Your Precision Project Today

Visit EMAR's official website to request a free DFM analysis and quote. Our engineering team will review your drawings and recommend the most cost-effective approach to achieve your precision requirements.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque