As a leading CNC Machining service provider, EMAR understands that cost is a critical factor for procurement managers and engineers sourcing precision aluminum components. This article provides transparent insights into pricing structures while highlighting our competitive advantages.

Factors Influencing CNC Aluminum Machining Costs

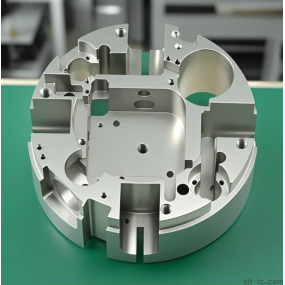

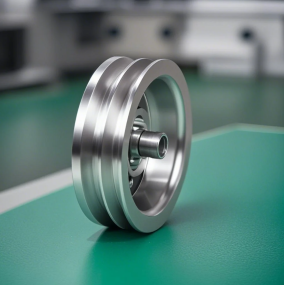

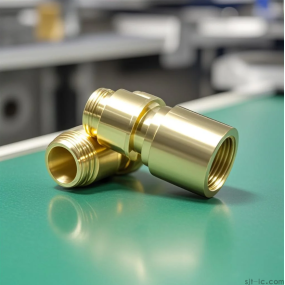

The final price depends on material grade (6061, 7075, etc.), part complexity, tolerances (±.001" to ±.005"), surface finishes (as-machined to anodized), and order volume. Our CNC aluminum machining services optimize these variables to deliver cost efficiency without compromising quality.

EMAR's Cost-Saving Advantages

With 18+ years of experience, we offer: 1) Multi-axis machining centers reducing setups, 2) Bulk material purchasing discounts, 3) DFM analysis to simplify geometries, and 4) Volume-based pricing tiers. Our ISO 9001-certified facility in China ensures consistent quality at 30-50% lower costs than Western counterparts.

Request instant quotes at www.sjt-ic.com with your 3D files.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque