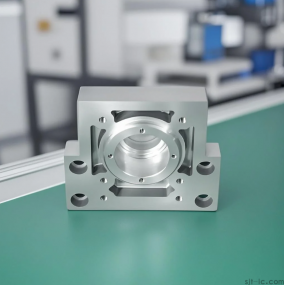

Understanding CNC Batch Processing Costs

When seeking CNC batch processing manufacturing quotation, clients need to consider multiple factors that influence pricing. At EMAR, we provide transparent and competitive pricing based on material selection, part complexity, quantity requirements, and surface finishing needs. Our advanced CNC Machining centers and optimized production workflows ensure cost-efficiency for bulk orders without compromising precision.

Key Factors Affecting Your CNC Batch Quote

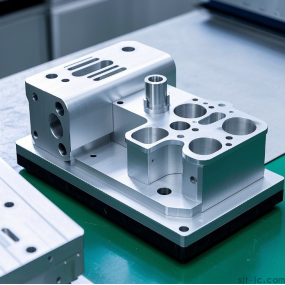

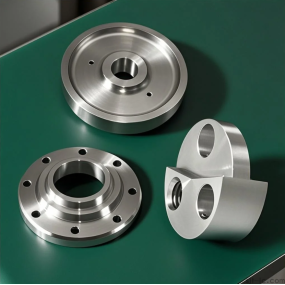

1. Material Costs: Different metals (aluminum, steel, titanium) and plastics have varying price points

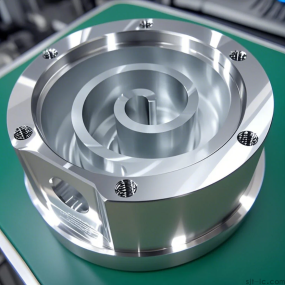

2. Machining Time: Complex geometries and tight tolerances increase production time

3. Order Volume: Higher quantities typically benefit from economies of scale

4. Secondary Operations: Additional processes like anodizing or heat treatment

5. Tooling Requirements: Specialized cutting tools may be needed for specific projects

EMAR's Competitive Advantages in Batch Production

As a professional CNC machining service provider, EMAR offers:

• 50+ high-precision CNC machines with automated tool changers

• ISO 9001-certified quality control systems

• Just-in-time manufacturing capabilities

• Dedicated project management for large orders

• Material traceability and full documentation

Optimizing Your Project for Cost Efficiency

Our engineers can help reduce your batch processing costs through:

• Design for Manufacturability (DFM) analysis

• Material selection guidance

• Process optimization recommendations

• Alternative finishing options

• Flexible production sche ** ng

Request Your Custom Quote Today

Visit our website at https://www.sjt-ic.com/ to submit your project details or contact our sales team for a personalized CNC batch processing manufacturing quotation. We typically respond within 24 hours with comprehensive pricing and lead time information for your specific requirements.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque