As a professional procurement manager or engineer, understanding aluminum CNC Machining prices is critical for budgeting and supplier selection. EMAR, a trusted CNC machining service provider (https://www.sjt-ic.com/), breaks down the key pricing factors and how we deliver cost-effective precision.

What Determines Aluminum CNC Machining Costs?

Four primary factors influence aluminum CNC machining quotes:

- Material Grade: 6061 vs. 7075 aluminum impacts raw material costs

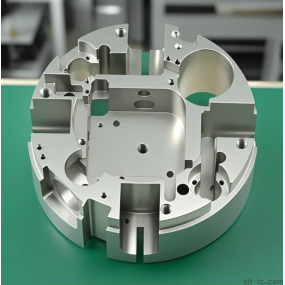

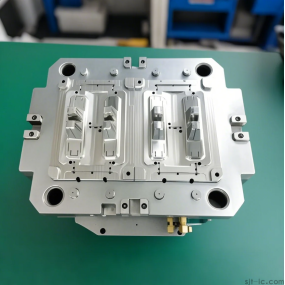

- Part Complexity: Multi-axis machining requirements increase programming time

- Surface Finish: Anodizing or polishing adds post-processing costs

- Order Volume: Bulk orders typically reduce per-unit pricing

EMAR's Competitive Advantage in Aluminum Machining

Our ISO 9001-certified facility optimizes costs through:

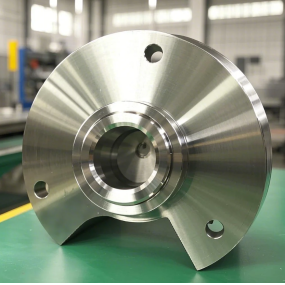

- Advanced 5-axis CNC machines for complex geometries

- In-house tooling department reducing external dependencies

- DFM (Design for Manufacturing) analysis to suggest cost-saving modifications

How to Get Accurate Aluminum CNC Quotes

For precise aluminum machining pricing, provide:

- 3D CAD files (STEP/IGES format preferred)

- Material specifications and tolerances

- Surface finish requirements

- Required lead time

EMAR offers free project evaluations within 24 hours. Visit https://www.sjt-ic.com/ to upload your design files or contact our engineering team for customized solutions balancing precision and budget.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque