Selecting the right CNC mold processing factory is critical for industries requiring high-precision components. EMAR, a professional CNC Machining service provider, offers insights into key evaluation criteria to ensure quality, efficiency, and cost-effectiveness.

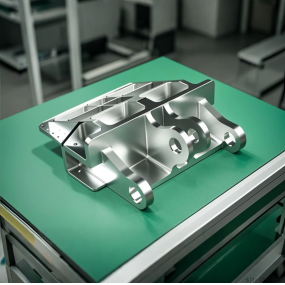

Technical Capabilities and Equipment

Advanced CNC machines (5-axis milling, Swiss-type lathes) and CAD/CAM software integration are prerequisites for complex mold fabrication. EMAR's facility houses ISO-certified equipment with ±.005mm tolerances.

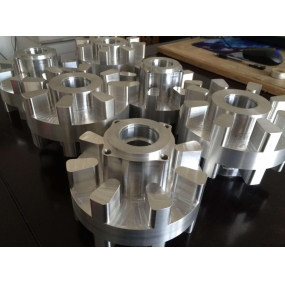

Material Expertise

Top factories should process diverse materials (aluminum, titanium, engineering plastics) with customized tooling solutions. Our metallurgical lab conducts material testing to prevent defects.

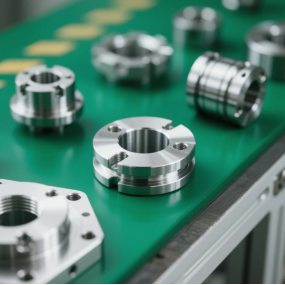

Quality Assurance Protocols

Look for factories implementing ISO 9001-certified QC processes, including CMM inspection and surface roughness analysis. EMAR provides full traceability reports with each shipment.

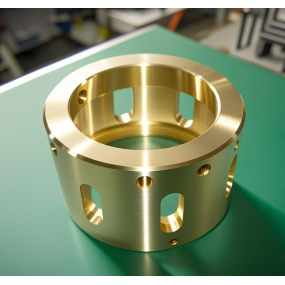

Industry-Specific Experience

Specialization matters - whether for automotive molds or medical device components. Our portfolio includes aerospace-grade molds with AS910 compliance.

Supply Chain Efficiency

Reliable factories offer DFM feedback, rapid prototyping (72-hour turnaround), and just-in-time production. EMAR's ERP system ensures on-time delivery with real-time project tracking.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque