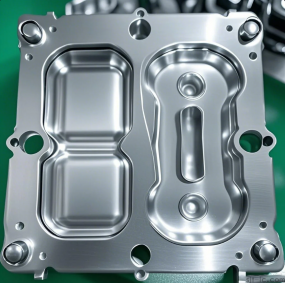

As a leading CNC Machining service provider, EMAR specializes in manufacturing high-precision valve components for industries ranging from oil & gas to aerospace. This article explores the technical advantages, material selection, and quality control processes behind our valve part production.

Why Choose CNC Machining for Valve Components?

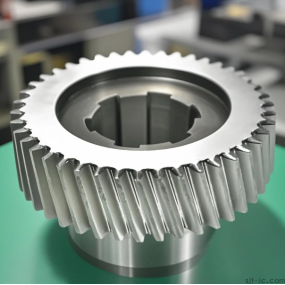

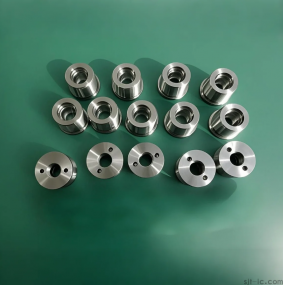

Valve systems demand extreme precision to ensure leak-proof operation and long service life. Our 5-axis CNC machines achieve tolerances within ±.005mm, critical for manufacturing:

- Valve bodies and housings

- Stems and seats

- Trim components

- Actuator interfaces

Material Expertise for Demanding Environments

We machine valve parts from:

- Stainless steel (304/316) for corrosion resistance

- Duplex steels for high-pressure applications

- Brass and bronze for water systems

- Exotic alloys like Inconel for extreme temperatures

Surface Treatment Solutions

Our post-machining treatments enhance component durability:

- Electropolishing for smooth fluid flow

- Hard chrome plating for wear resistance

- PTFE coatings for chemical compatibility

EMAR's CNC machining capabilities ensure your valve components meet API, ASME, and ISO standards. With in-house CMM inspection and pressure testing, we guarantee performance reliability for mission-critical applications.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque