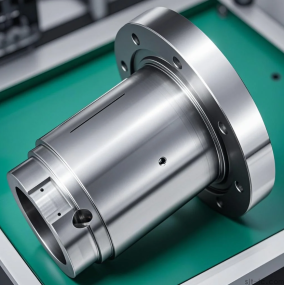

When it comes to crankshaft CNC Machining, precision and durability are non-negotiable. At EMAR, we specialize in delivering high-performance machined crankshafts tailored for automotive, marine, and industrial applications. Our advanced CNC technology ensures micron-level accuracy, meeting the strictest industry standards.

Why Choose CNC Machining for Crankshafts?

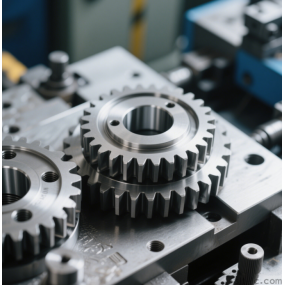

Traditional manufacturing methods often fall short in achieving the complex geometries and tight tolerances required for modern crankshafts. CNC machining eliminates these limitations through:

5-axis simultaneous milling for intricate counterweight profiles

Automated turning processes with live tooling capabilities

Consistent surface finishes below Ra .8μm

Material flexibility (alloy steels, forged steel, ductile iron)

EMAR's Crankshaft Manufacturing Process

Our CNC machining workflow combines German-engineered equipment with proprietary quality controls:

Material Certification: Traceable alloy verification

Rough Machining: Billet preparation with 30% excess material

Heat Treatment: Induction hardening for wear resistance

Finish Machining: ±.005mm journal diameter tolerance

Surface Enhancement: Shot peening for fatigue resistance

Industries We Serve

From high-rpm racing engines to heavy-duty diesel applications, our crankshafts deliver:

Automotive: Balanced designs for vibration reduction

Marine: Corrosion-resistant coatings

Power Generation: Oversized bearing surfaces

Aerospace: Lightweight titanium options

Quality Assurance Protocol

Every EMAR crankshaft undergoes:

3D scanning against CAD models

Ultrasonic testing for internal defects

Dynamic balancing to G2.5 standards

72-hour endurance simulation

With ISO 9001:2015 certification and 15+ years of crankshaft CNC machining experience, EMAR guarantees components that outperform OEM specifications. Request your free machining consultation today at www.sjt-ic.com.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque