As a leading CNC Machining service provider, EMAR specializes in high-volume production of precision metal components. Our advanced manufacturing capabilities ensure consistent quality and cost-effectiveness for industrial buyers and engineers seeking reliable Batch Processing of CNC Metal Parts solutions.

The Process of High-Volume CNC Metal Parts Manufacturing

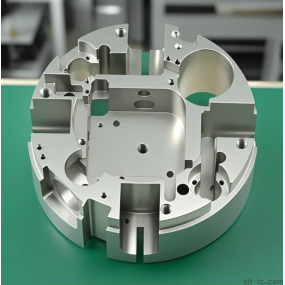

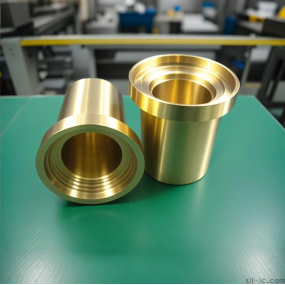

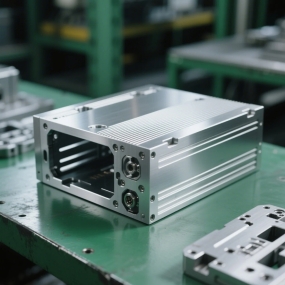

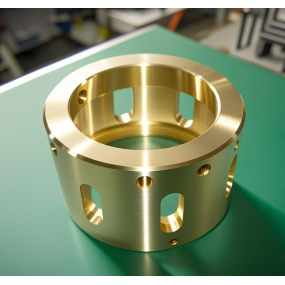

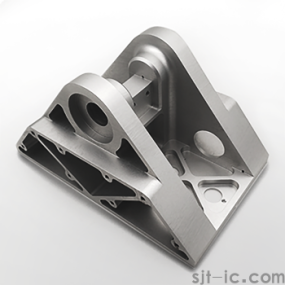

Our streamlined workflow begins with DFM analysis to optimize your designs for mass production. Using multi-axis CNC centers and automated tool changers, we achieve tight tolerances (±.01mm) while maintaining production efficiency. The process includes material selection, precision machining, quality inspection, and surface treatment - all executed under ISO 9001-certified standards.

Why Choose EMAR for Your Bulk CNC Components

1. Scalable Capacity: 50+ CNC machines dedicated to batch processing

2. Material Expertise: Aluminum, brass, stainless steel, and alloy options

3. Cost Advantage: 15-30% lower unit costs compared to standard shops

4. Quality Assurance: Full-dimensional reports with CMM inspection

Applications Across Industries

Our high-volume CNC services support automotive, electronics, medical device, and industrial equipment manufacturers. Typical products include precision shafts, enclosures, connectors, and complex mechanical assemblies requiring thousands of identical components.

Visit EMAR's official website to request a free project evaluation and discover how our CNC Batch Processing solutions can optimize your supply chain.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque