As a leading CNC automotive parts machining provider, EMAR Company specializes in delivering high-precision components for the automotive industry. Our advanced CNC Machining capabilities ensure that every part meets the strictest quality standards required by modern vehicles.

Why Choose CNC Machining for Automotive Parts?

The automotive industry demands components with exceptional precision, durability, and consistency. CNC machining offers the perfect solution, providing:

Tolerances within ±.005mm for critical components

Superior surface finishes that reduce friction and wear

Repeatable quality across large production runs

Compatibility with various automotive-grade materials

Our CNC Automotive Parts Machining Capabilities

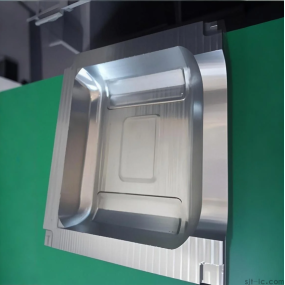

At EMAR, we utilize state-of-the-art 5-axis CNC machines to manufacture complex automotive components including:

Engine components (blocks, cylinder heads, pistons)

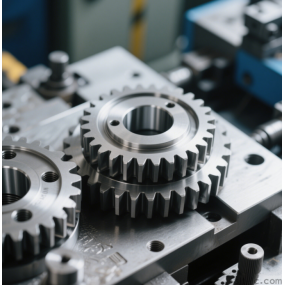

Transmission parts (gears, shafts, housings)

Suspension components (control arms, knuckles)

Brake system parts (calipers, brackets)

Material Expertise for Automotive Applications

We work with all industry-standard materials including aluminum alloys, stainless steel, titanium, and engineered plastics. Our material selection process considers:

Strength-to-weight requirements

Thermal and corrosion resistance

Cost-effectiveness for mass production

Quality Assurance in CNC Automotive Parts Manufacturing

Our quality control process includes:

First-article inspection (FAI)

In-process dimensional verification

Surface roughness testing

Material certification

Final comprehensive inspection

With EMAR's CNC machining services, automotive manufacturers and suppliers receive components that meet or exceed OEM specifications. Our expertise in CNC automotive parts machining ensures reliable performance, extended service life, and perfect fitment for your vehicle systems.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque