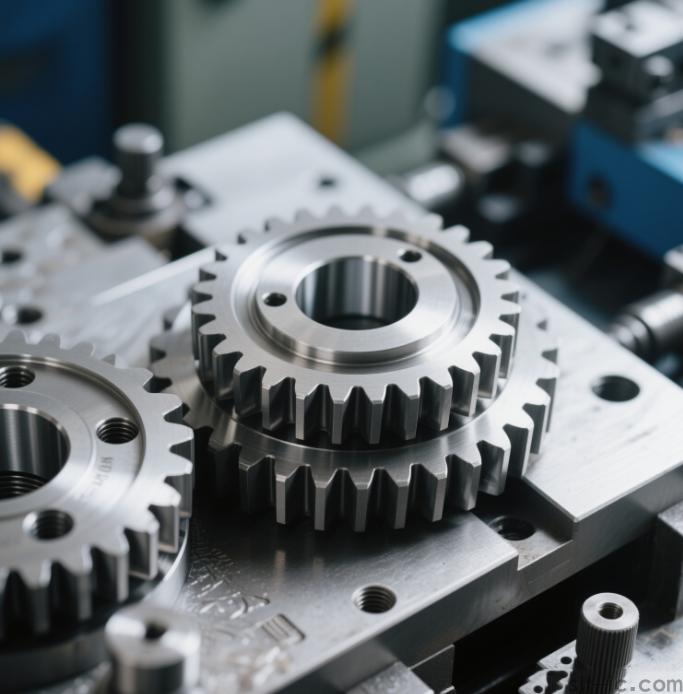

〖CNC Gear Machining Process Steps〗

In short, it follows four steps: Rough Machining → Finish Machining → Heat Treatment → Polishing!

1. First, use a lathe to mill the rough contour of the gear blank (rough machining), leaving a small amount of machining allowance.

2. Then, use a finish milling cutter to refine the tooth profile to ensure meshing accuracy.

3. Conduct heat treatment such as quenching to enhance hardness.

4. Finally, perform polishing to reduce surface roughness.

A tip: For thin-walled gears, machine the inner hole first before refining the outer teeth; otherwise, it is prone to tool vibration and tooth chipping!

〖How Much Does a CNC-Machined Gear Cost?〗

The cost depends on material, precision, and production volume!

- A single ordinary steel gear usually costs 200-500 RMB, and the unit price can be reduced to less than 100 RMB for mass production.

- High-precision helical gears may cost over 1,000 RMB each because they require 5-axis CNC machines.

Here’s an example: For a steel gear with a modulus of 2 and a tolerance of ±0.05mm, the unit price is about 120 RMB for a batch of 100 pieces. If surface nitriding treatment is added, an additional 20% cost will be incurred 😅.

For small-batch production, 3D printing is more cost-effective; CNC Machining is better suited for large-batch production!

〖CNC Machining Parameters for Small-Size Gears〗

- Spindle speed: 3000-5000 rpm

- Feed rate: 0.1 mm/tooth

For small-size gears (e.g., modulus < 1), use small-diameter milling cutters to avoid tooth extrusion. Recommended parameters are as follows:

- Rough machining: Speed = 3000 rpm, Feed rate = 0.15 mm/tooth, Cutting depth = 0.5 mm

- Finish machining: Speed = 5000 rpm, Feed rate = 0.05 mm/tooth, Cutting depth = 0.1 mm

Key point: Ensure an adequate supply of cutting fluid; otherwise, the tool will wear out quickly and the tooth surface finish will be affected!

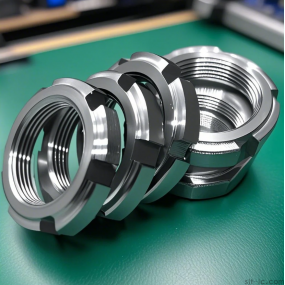

〖CNC Gear Machining Precision Control〗

The core lies in tool compensation and machine calibration! Precision issues usually arise from the following reasons:

1. Tool wear: Check the cutting edge every 20 workpieces processed.

2. Loose clamping: Hydraulic clamps provide more stability than mechanical clamps.

3. Thermal deformation: Pause the machine for 10 minutes to cool down midway during machining.

Personal test result: Regularly measure the machine’s positioning accuracy with a laser calibrator, which can directly reduce the tolerance to within ±0.01 mm!

〖Precautions for CNC Machining of Quenched Gears〗

After quenching, the gear must undergo annealing before finish machining! Direct milling will not only easily cause tooth cracking but also lead to severe tool chipping (to the point of being unrecognizable) 😂.

The correct sequence is: Rough Machining → Quenching → Annealing → Finish Machining → Secondary Polishing.

Use oil-based cutting fluid; water-based fluid tends to make the quenched layer brittle. Additionally, for thin gears, perform stress relief first (e.g., aging treatment); otherwise, the deformation will be so severe that it’s frustrating!

Personal Insight

CNC machining for gears is truly efficient, but beginners often make mistakes—for example, randomly setting parameters resulting in a tooth surface as rough as sandpaper!

In fact, paying more attention to long-tail keywords to identify user needs (such as "remedies for CNC gear machining tool breakage") can bring accurate traffic and make it easier to rank well. Next time before programming, search for how users ask questions; it will definitely broaden your thinking! ✨

If you need, I can help you organize an English-Chinese comparison table of core CNC gear machining terms to make it easier for you to reference in cross-border communication or document reading.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque