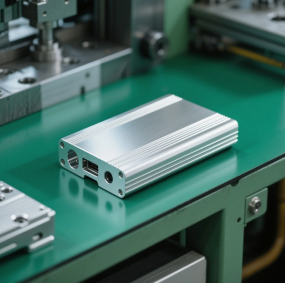

As a leading CNC production OEM manufacturing company, EMAR specializes in delivering precision-engineered solutions for industries requiring high-quality machined components. Our advanced CNC capabilities and strict quality control processes ensure exceptional results for every project.

What Does a CNC Production OEM Manufacturer Do?

A professional CNC production OEM manufacturing company provides complete contract machining services, handling everything from material procurement to final inspection. We utilize state-of-the-art CNC machines (3-axis to 5-axis) to produce precision parts according to client specifications, offering services including prototyping, small-batch production, and large-volume manufacturing.

Key Advantages of Partnering with EMAR

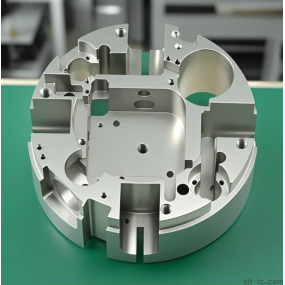

1. Precision Engineering: ±.01mm tolerance capability for critical dimensions

2. Material Expertise: Working with aluminum, steel, titanium, and engineering plastics

3. Quality Assurance: ISO 9001 certified with full inspection reports

4. Scalable Capacity: Flexible production from prototypes to 100,000+ units

Our CNC Production Process

The workflow at our CNC production OEM manufacturing facility follows these critical stages:

1. Design Review & DFM Analysis

2. Material Selection & Preparation

3. Precision Machining Operations

4. Surface Treatment & Finishing

5. Comprehensive Quality Inspection

6. Packaging & Logistics

Visit EMAR's official website to explore our full CNC Machining capabilities and request a free project evaluation. Our engineering team stands ready to optimize your designs for manufacturability and cost-efficiency.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque