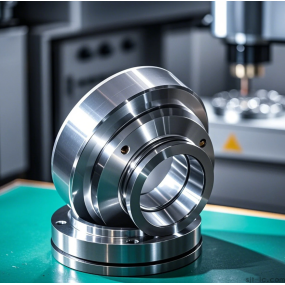

What is Precision Parts CNC Machining?

Precision parts CNC machining is a high-accuracy manufacturing process that utilizes computer-controlled machines to produce intricate components with tight tolerances. At EMAR, we specialize in delivering CNC-machined precision parts for industries such as aerospace, medical, automotive, and electronics, ensuring exceptional quality and repeatability.

Key Advantages of CNC Machining for Precision Components

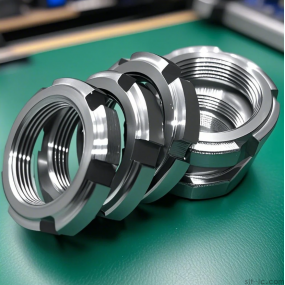

1. Ultra-Tight Tolerances: Achieve micron-level precision (±.005mm or better) for critical applications.

2. Material Versatility: Process metals (aluminum, titanium, stainless steel), plastics, and engineered composites.

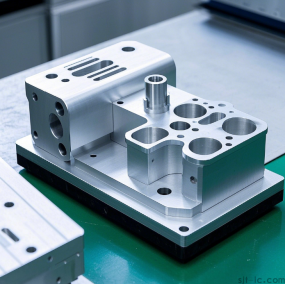

3. Complex Geometry: Produce intricate shapes, thin walls, and micro-features with 3/4/5-axis machining.

4. Surface Finish Excellence: Deliver Ra .2μm or better through advanced post-processing techniques.

EMAR's Precision CNC Machining Capabilities

Our CNC precision machining services include:

• Multi-axis milling (up to 5-axis simultaneous machining)

• Swiss-type turning for micro-parts

• High-speed machining for delicate features

• CMM inspection with 100% quality assurance

Industries We Serve

EMAR's precision machined components are trusted by:

• Medical device manufacturers (surgical instruments, implants)

• Aerospace & defense (turbine blades, guidance systems)

• Automotive (fuel injection systems, transmission parts)

• Semiconductor (wafer handling components)

Why Choose EMAR for Your Precision Machining Needs?

1. ISO 9001:2015 Certified quality management system

2. Advanced Metrology Lab with Zeiss CMM and optical comparators

3. Material Traceability from certified suppliers

4. Prototype to Production support with fast turnaround

Contact EMAR today at www.sjt-ic.com to discuss your precision CNC machining requirements with our engineering team.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque