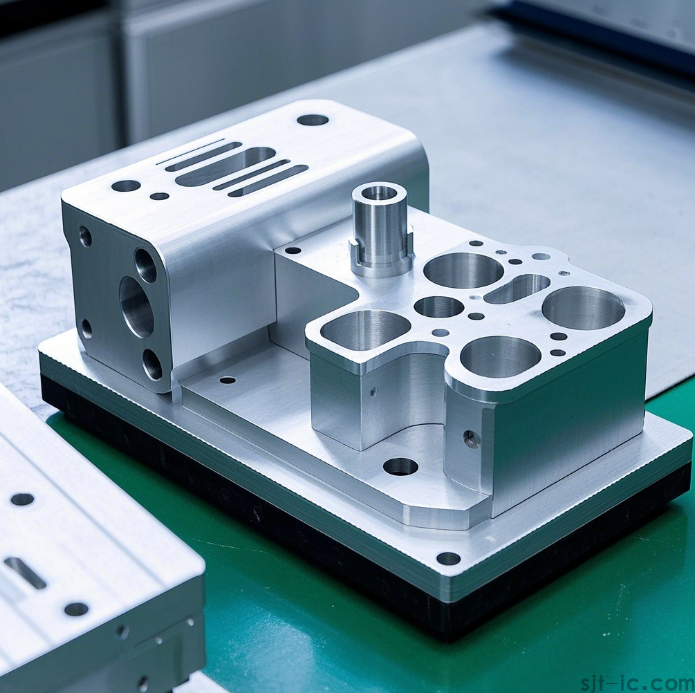

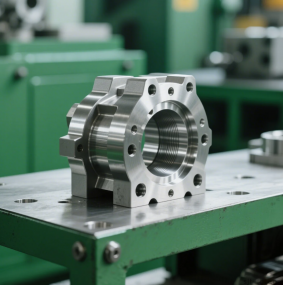

What Are CNC Machining Structural Components?

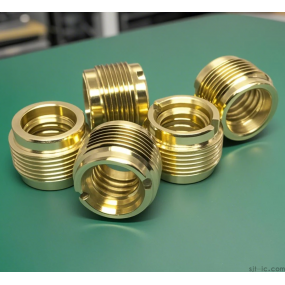

CNC machining structural components refer to precision-engineered parts manufactured through computer numerical control (CNC) technology, designed to bear loads or provide framework support in various industrial applications. These components are critical in industries ranging from aerospace to automotive, where dimensional accuracy and material integrity are paramount.

Why Choose CNC for Structural Components?

CNC technology offers unmatched advantages for producing structural parts:

Tight tolerances (up to ±.005mm) ensure perfect fit and function

Superior material consistency compared to traditional fabrication

Complex geometries achievable in single setups

Repeatable quality for mass production

At EMAR, our 5-axis CNC machining centers can handle structural components up to 2m in length with micron-level precision.

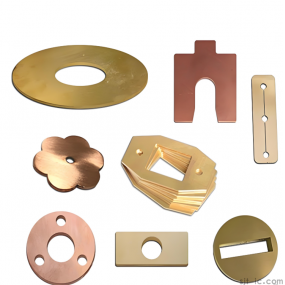

Material Selection for Structural Components

We machine structural parts from:

Aluminum alloys (6061-T6, 7075) - 40% lighter than steel

Titanium (Grade 5) - Ultimate strength-to-weight ratio

Stainless steel (304, 316) - Corrosion resistance

Engineering plastics (PEEK, Delrin) - For specialized applications

Our material engineers help select optimal alloys based on your load requirements and environmental factors.

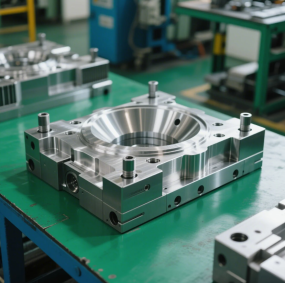

EMAR's Quality Assurance Process

Every CNC machined structural component undergoes:

In-process dimensional checks with CMM

Surface roughness verification (Ra .8μm achievable)

Material certification review

Final assembly testing when applicable

We maintain ISO 9001:2015 certification and provide full traceability documentation.

Applications Across Industries

Our CNC structural parts serve critical functions in:

Aerospace: Wing ribs, engine mounts

Automotive: Chassis components, suspension parts

Medical: Imaging equipment frames

Industrial: Robotic arm structures

With over 15 years in precision manufacturing, EMAR has delivered structural solutions for Fortune 500 companies and innovative startups alike.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque