High carbon steel is a critical material in industries demanding exceptional strength and wear resistance. As a leading CNC Machining specialist, EMAR leverages advanced technology to transform this challenging material into precision components for aerospace, automotive, and tooling applications.

Why Choose CNC Machining for High Carbon Steel?

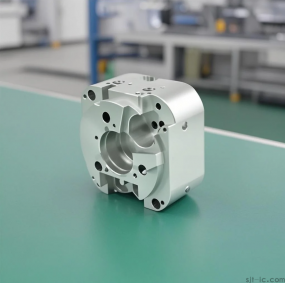

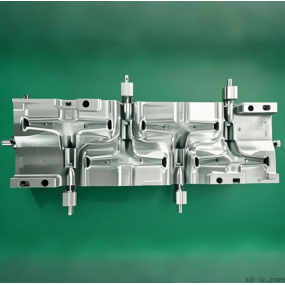

With carbon content exceeding .6%, high carbon steel presents unique machining challenges due to its hardness. Our 5-axis CNC machines equipped with carbide tooling and optimized cooling systems ensure:

±.005mm dimensional accuracy

Superior surface finishes (Ra .8μm achievable)

Minimal thermal deformation

Efficient batch production consistency

EMAR's Technical Edge in High Carbon Steel Processing

Our CNC machining center implements proprietary techniques to overcome material limitations:

Pre-machining annealing to reduce hardness for roughing operations

Adaptive toolpaths that compensate for tool wear in real-time

Cryogenic cooling solutions for critical tolerance features

Post-process heat treatment to restore optimal material properties

Applications Across Industries

From surgical instrument components to hydraulic system parts, our CNC machined high carbon steel solutions serve diverse sectors requiring:

Cutting tools and dies with extended service life

Wear-resistant industrial machine components

High-stress automotive transmission parts

Precision measurement equipment frames

With ISO 9001-certified processes and DFM support, EMAR delivers high carbon steel components that meet ASME and DIN standards. Contact our engineering team for project-specific solutions combining material expertise with CNC precision.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque