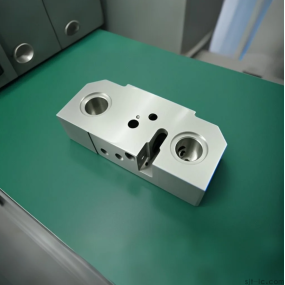

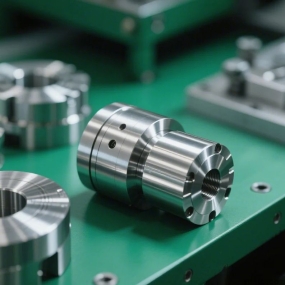

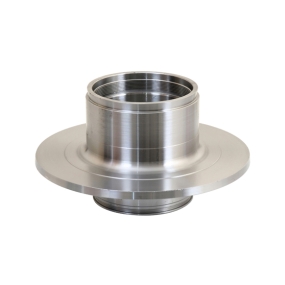

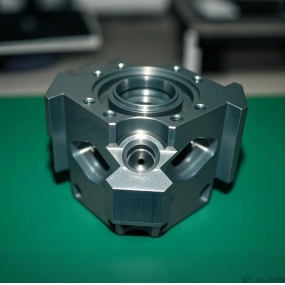

In modern manufacturing, copper parts CNC batch machining plays a pivotal role across industries like electronics, automotive, and aerospace. As a trusted CNC Machining service provider, EMAR delivers high-volume production with micron-level accuracy, ensuring cost-effectiveness without compromising quality.

Why Choose CNC Batch Machining for Copper Parts?

Copper's exceptional conductivity and thermal properties demand specialized machining approaches. Our CNC milling and turning centers equipped with coolant-fed tooling prevent material galling while maintaining ±.01mm tolerances. For batch production, we implement:

Automated tool changers for uninterrupted operation

Multi-pallet systems reducing idle time

In-process gauging for real-time quality control

EMAR's Technical Capabilities

Our 15+ years of experience in copper machining translates to:

| Parameter | Specification |

|---|

| Maximum Batch Size | 50,000+ pieces per order |

| Surface Finish | Ra .4μm achievable |

| Material Grades | C11000, C10100, C14500, etc. |

Industry-Specific Solutions

We customize machining strategies based on application requirements:

Electronics: RF shielding components with EMI-proof tolerances

Automotive: High-strength bushings with oil-impregnation features

Energy: Heat exchanger parts with optimized thermal transfer surfaces

Quality Assurance Protocol

Every batch undergoes rigorous inspection including:

First-article PPAP documentation

Statistical process control (SPC) charts

3D scanning for complex geometries

Conductivity testing for electrical components

At EMAR, we combine advanced CNC technology with metallurgical expertise to deliver copper parts that meet your most demanding specifications. Contact our engineering team for a DFM analysis and batch production quote today.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque