In the lighting industry, CNC Machining for lighting fixtures has become a game-changer, enabling manufacturers to achieve unparalleled precision and design flexibility. As a leading CNC machining service provider, EMAR specializes in delivering high-quality components for architectural, commercial, and decorative lighting applications.

Why Choose CNC Machining for Lighting Components?

Modern lighting designs demand complex geometries and tight tolerances that traditional manufacturing methods struggle to achieve. Our CNC machining processes offer:

±.005mm precision for perfect optical alignment

Seamless integration of heat dissipation features

Material versatility (aluminum, brass, acrylic, etc.)

Surface finish options from matte to mirror polish

EMAR's Advanced Lighting Fixture Manufacturing Capabilities

Our 5-axis CNC centers and Swiss-type lathes produce:

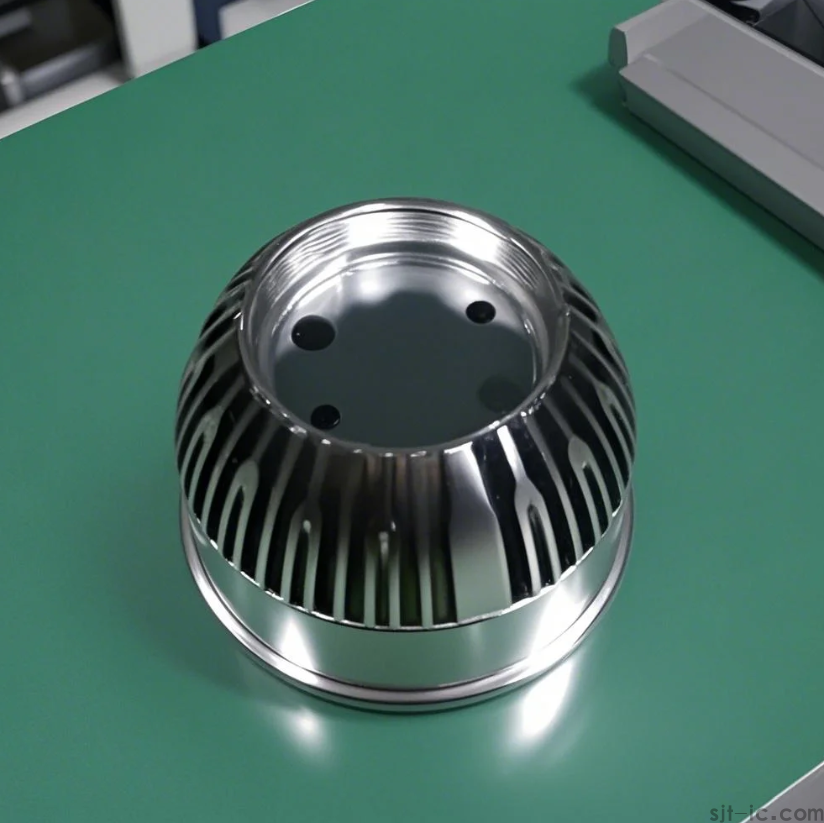

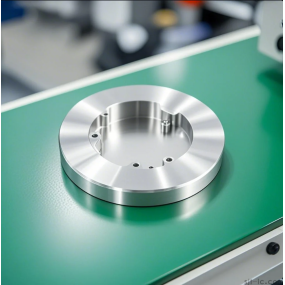

Precision reflectors and housings

Heat sinks for LED applications

Decorative metal trim components

Custom mounting brackets and adapters

Material Selection Guidance for Lighting Applications

We help clients select optimal materials based on:

Thermal conductivity requirements

Weight constraints

Aesthetic considerations

Outdoor vs. indoor applications

Quality Assurance Process

Every lighting component undergoes rigorous inspection including:

CMM verification of critical dimensions

Surface roughness testing

Assembly fit checks

Material certification validation

At EMAR, we combine engineering expertise with state-of-the-art CNC technology to deliver lighting components that meet the most demanding specifications. Contact our technical team today to discuss your specific lighting fixture machining requirements.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque