As a leading CNC Machining service provider, EMAR specializes in manufacturing high-performance CNC machining guide wheels for diverse industrial applications. This article explores the technical specifications, manufacturing process, and advantages of our precision-engineered guide wheels.

What is a CNC Machining Guide Wheel?

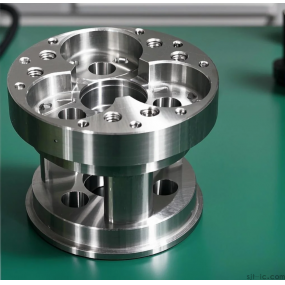

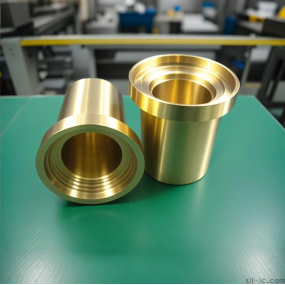

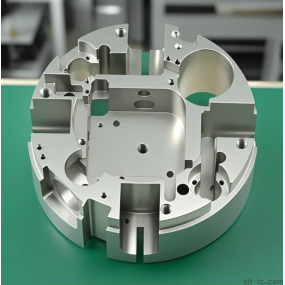

A CNC machining guide wheel is a critical component in linear motion systems, designed to maintain precise alignment and reduce friction in industrial machinery. Our guide wheels are manufactured using advanced 5-axis CNC machines, ensuring micron-level accuracy and exceptional durability.

Key Features of EMAR's CNC Machined Guide Wheels

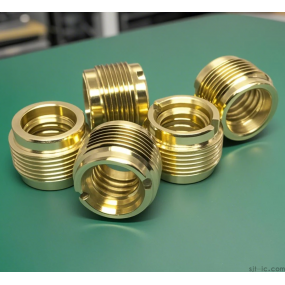

1. Material Selection: Available in aluminum alloy, stainless steel, or engineering plastics

2. Precision Tolerance: ±.01mm dimensional accuracy

3. Surface Treatment: Anodizing, hardening, or special coatings available

4. Load Capacity: Custom designs for various load requirements

Manufacturing Process at EMAR

Our guide wheel production follows a rigorous 6-step quality control process:

1. Material inspection and preparation

2. CNC turning/milling operations

3. Precision grinding for bearing surfaces

4. Surface treatment application

5. Dynamic balancing testing

6. Final quality inspection

Why Choose EMAR for Your Guide Wheel Needs?

With 15+ years of CNC machining experience, EMAR offers:

- Custom design and engineering support

- Fast prototyping (3-5 day turnaround)

- Competitive pricing for bulk orders

- ISO 9001 certified quality management

Contact our technical team at www.sjt-ic.com to discuss your specific guide wheel requirements and receive a free project evaluation.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque