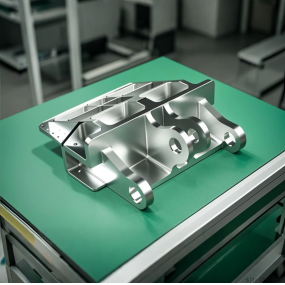

As a leading CNC Machining service provider, EMAR specializes in manufacturing high-precision conveyor table components for industrial automation systems. Our advanced CNC technology ensures dimensional accuracy and durability for these critical parts that keep production lines running smoothly.

What Are CNC Machined Conveyor Table Components?

These refer to the precisely engineered parts that form the structural and functional elements of material handling systems, including guide rails, mounting brackets, roller supports, and alignment fixtures. EMAR's CNC machining capabilities allow us to produce these components with tolerances as tight as ±.005mm.

Key Advantages of Our CNC Machining Process

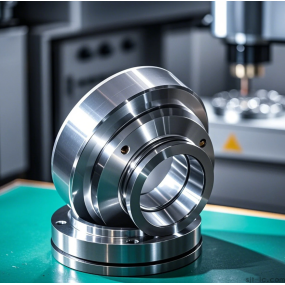

1. Material Versatility: We machine aluminum alloys, stainless steel, and engineering plastics to suit different operational environments.

2. Surface Finish Options: From anodizing to powder coating for corrosion resistance.

3. Rapid Prototyping: 3-5 day turnaround for design validation samples.

Why Choose EMAR for Your Conveyor Components?

Our CNC machining center features:

• 5-axis simultaneous machining capability

• Automated quality inspection systems

• ISO 9001-certified production processes

Visit our website to request a free DFM analysis for your conveyor system parts.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque