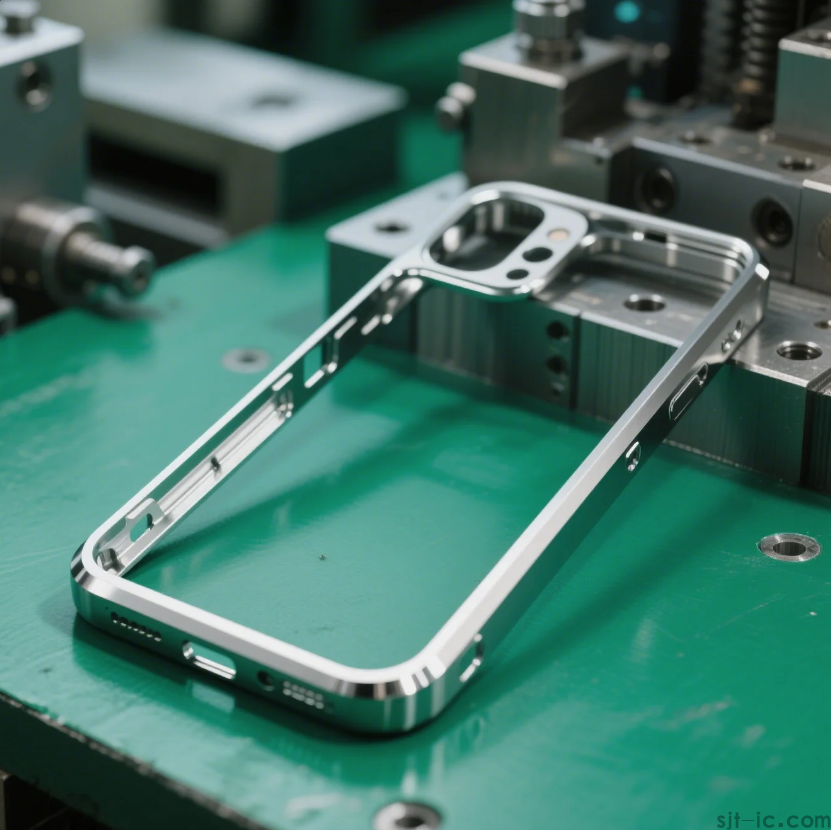

As a leading CNC Machining service provider, EMAR specializes in manufacturing high-precision components for mobile devices. This article explores the technical aspects of producing mobile phone parts through advanced CNC processes.

Why Choose CNC Machining for Mobile Phone Components?

Mobile phone manufacturing demands micron-level precision and exceptional surface finishes. CNC machining offers several advantages:

Tolerances as tight as ±.01mm

Superior surface quality (Ra .4μm achievable)

Material versatility (aluminum, stainless steel, titanium, engineering plastics)

Rapid prototyping capabilities

Key Mobile Phone Parts Manufactured via CNC

Our CNC machining services produce critical components including:

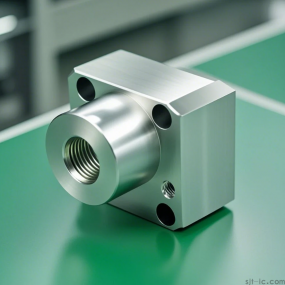

Metal frames and chassis

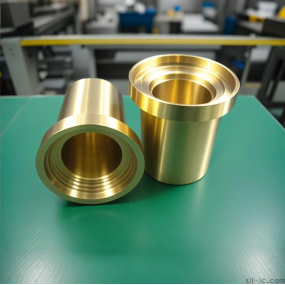

Precision buttons and connectors

Camera mounts and lens housings

Antenna components

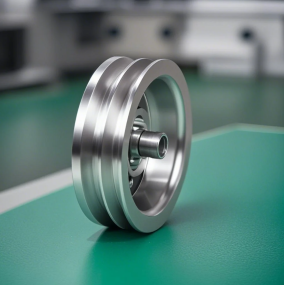

Heat dissipation elements

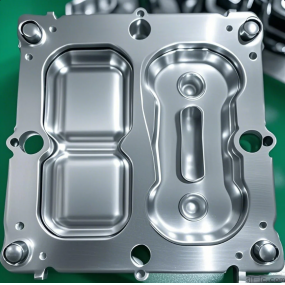

EMAR's Advanced CNC Capabilities

Our facility features:

5-axis CNC machines for complex geometries

Swiss-type lathes for micro-components

In-process quality control systems

Automated post-processing solutions

Quality Assurance Process

Every mobile phone component undergoes rigorous inspection:

Coordinate Measuring Machine (CMM) verification

Surface roughness testing

Material composition analysis

Functional testing under simulated conditions

EMAR's expertise in CNC machining for mobile devices ensures reliable, high-performance components that meet the stringent requirements of the electronics industry. Contact our technical team at www.sjt-ic.com for your mobile phone part manufacturing needs.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque