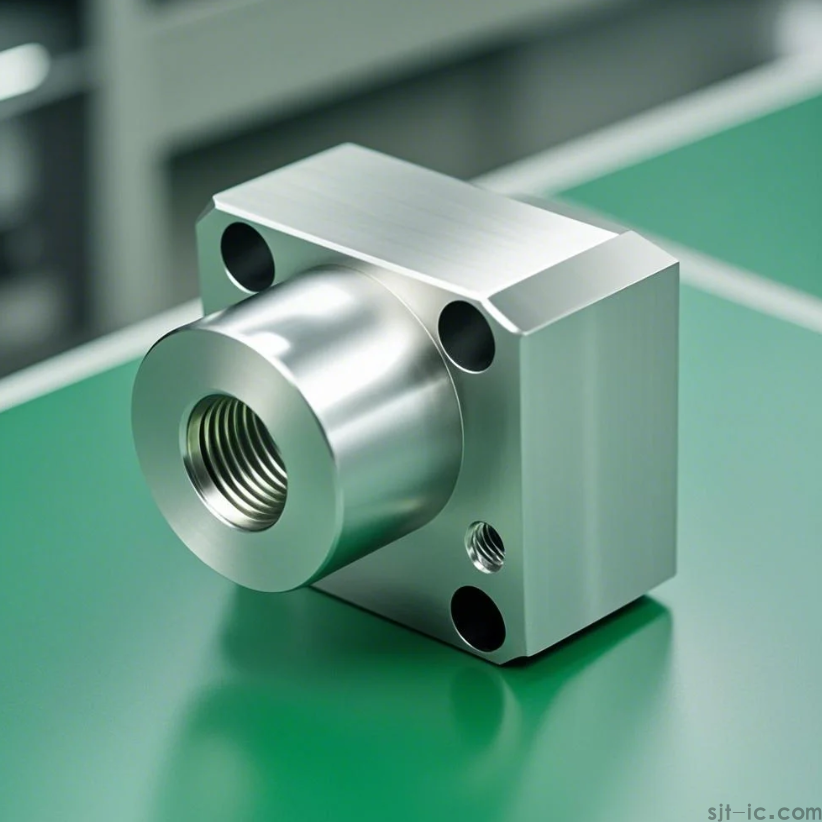

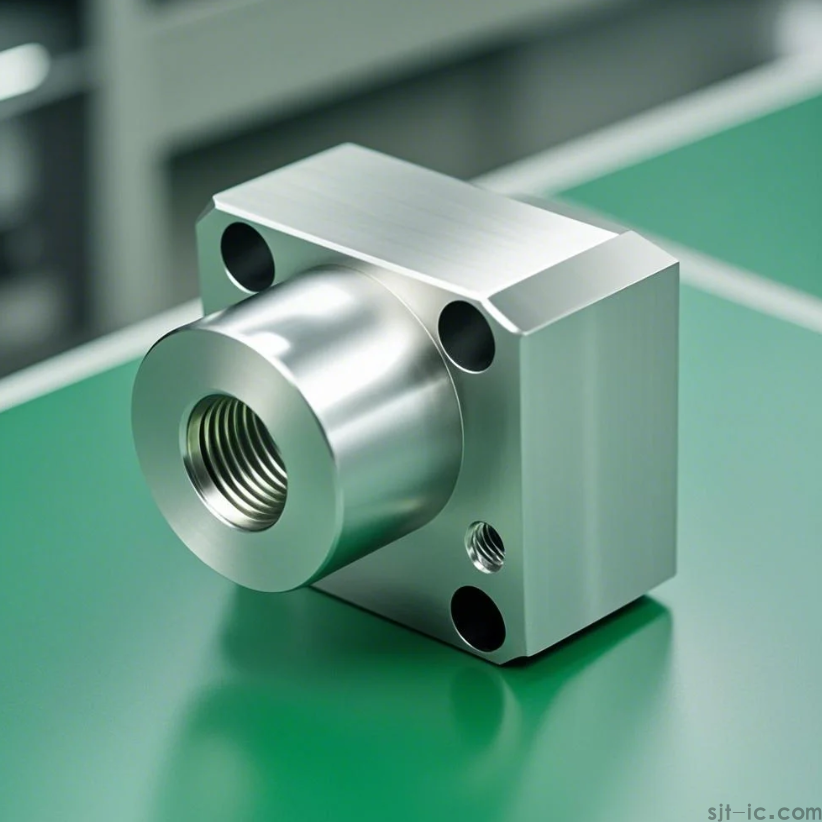

When it comes to aluminum parts CNC Machining, precision, efficiency, and material expertise are critical. At EMAR, we specialize in delivering high-quality CNC-machined aluminum components for industries ranging from aerospace to automotive. Our advanced CNC technology ensures tight tolerances, excellent surface finishes, and cost-effective production for both prototypes and large-scale orders.

Why Choose CNC Machining for Aluminum Parts?

Aluminum is a preferred material for CNC machining due to its lightweight, corrosion resistance, and excellent machinability. Our CNC machining processes leverage high-speed cutting tools and multi-axis capabilities to produce complex geometries with repeatable accuracy. Whether you need aluminum enclosures, brackets, or custom fittings, EMAR's machining solutions guarantee dimensional stability and rapid turnaround.

EMAR's Aluminum CNC Machining Capabilities

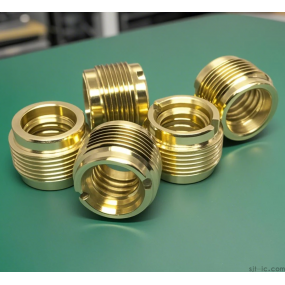

Our facility is equipped with state-of-the-art CNC mills and lathes capable of handling aluminum alloys like 6061, 7075, and 5052. Key services include:

3/4/5-axis CNC milling for intricate contours and pockets

CNC turning for precision shafts and cylindrical parts

Secondary operations (anodizing, powder coating, etc.)

Quality Assurance in Every Step

EMAR implements rigorous inspection protocols using CMMs and optical comparators to ensure every aluminum CNC machined part meets ISO 9001 standards. Our engineers optimize tool paths to minimize material waste while maintaining ±.005mm tolerances for critical applications.

Industries We Serve

From medical device components to automotive lightweighting solutions, our aluminum machining expertise supports diverse sectors requiring high strength-to-weight ratios and thermal conductivity.

Partner with EMAR for reliable, precision aluminum CNC machining. Contact our team today for a customized quote or DFM consultation.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque