As a professional CNC Machining service provider, EMAR often receives inquiries about copper CNC machining cost. Understanding the factors that influence pricing is crucial for procurement managers, engineers, and business owners to make informed decisions and effectively budget their projects.

Factors Influencing Copper CNC Machining Costs

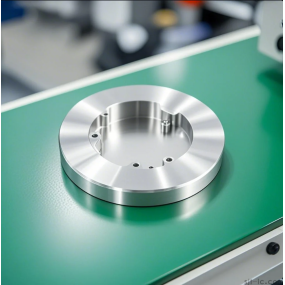

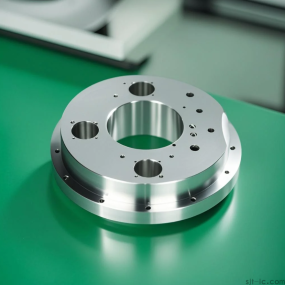

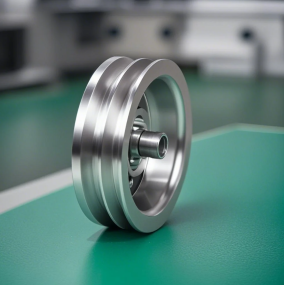

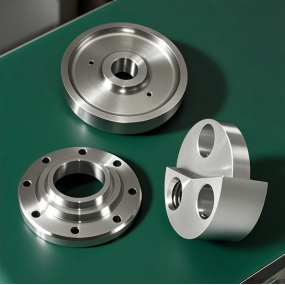

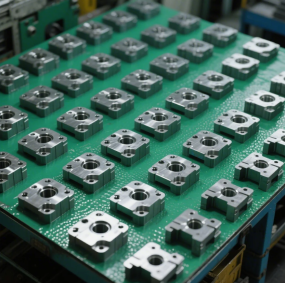

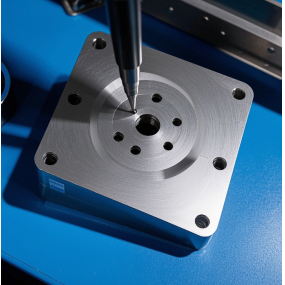

The cost of CNC machining copper parts is not a fixed value; it depends on several key factors. The primary elements include the complexity of the part design, the quantity of parts required, the type of copper alloy used, the machining time, and the required post-processing finishes. More complex geometries with tight tolerances require longer machining time and more sophisticated tooling, increasing the cost. Similarly, smaller batch sizes have a higher cost per part due to setup time, while larger volumes benefit from economies of scale.

Material Cost: Copper Alloys

The choice of copper alloy significantly impacts the overall machining cost. Pure copper is very soft and gummy, making it challenging to machine and often leading to higher tool wear. Alloys like C11000 (Electrolytic Tough Pitch Copper) are more common. However, free-machining alloys such as C36000 (Brass) are specifically designed for CNC machining, offering better chip breaking and longer tool life, which can reduce overall machining expenses. The raw material cost per kilogram also varies between these alloys.

How to Get an Accurate Quote from EMAR

To obtain a precise and competitive quote for your copper CNC machining project, providing a detailed 3D model (e.g., STEP, IGES) and 2D drawings is essential. This allows our engineers at EMAR to analyze the design for manufacturability (DFM), select the appropriate copper alloy, and calculate the exact machining time. You can easily submit your files through our website https://www.sjt-ic.com/ for a fast and transparent cost calculation. We pride ourselves on offering high-quality machining, consistent results, and clear communication throughout the quoting and manufacturing process.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque