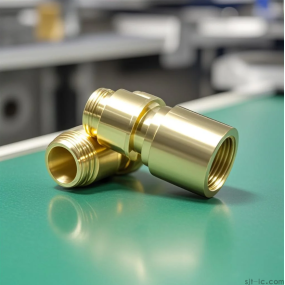

As a leading CNC Machining service provider, EMAR specializes in manufacturing high-precision copper gears for various industrial applications. This article will explore the technical process and advantages of our copper gear production.

Why Choose Copper for Gear Manufacturing?

Copper alloys offer exceptional properties for gear applications, including excellent thermal conductivity, corrosion resistance, and natural lubricity. These characteristics make CNC machined copper gears ideal for demanding environments in automotive, aerospace, and industrial machinery.

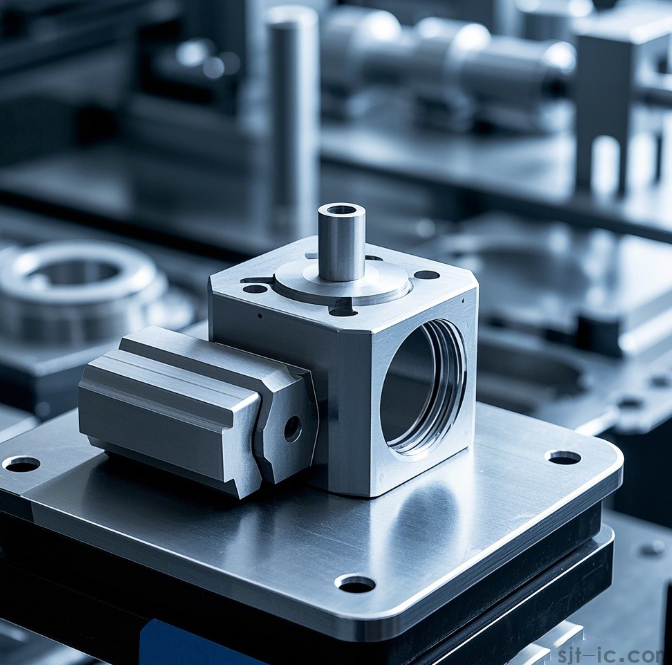

Our CNC Machining Process for Copper Gears

EMAR follows a rigorous 6-step manufacturing process:

Material selection: Using premium C11000 electrolytic copper or specific copper alloys

CAD/CAM programming: Creating optimized tool paths for gear tooth profiles

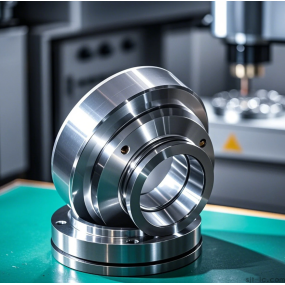

Precision machining: Utilizing 5-axis CNC machines for complex geometries

Quality inspection: Implementing CMM and gear measurement systems

Surface treatment: Applying specialized finishes when required

Final testing: Conducting load and durability assessments

Technical Advantages of EMAR's CNC Gear Manufacturing

Our CNC machining capabilities deliver copper gears with:

Dimensional accuracy within ±.005mm

Surface finish up to Ra .4μm

Custom tooth profiles including spur, helical, and bevel gears

Production capacity from prototypes to mass production

Industry Applications

Our precision copper gears serve critical functions in:

Power transmission systems

Robotics and automation equipment

Marine propulsion systems

Medical device mechanisms

Why Partner with EMAR?

EMAR combines advanced CNC technology with metallurgical expertise to produce copper gears that outperform industry standards. Our ISO 9001-certified facility ensures consistent quality, while our engineering team provides technical support throughout your project lifecycle.

For your next copper gear requirement, visit our website at https://www.sjt-ic.com/ to request a quote or consult with our technical specialists.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque