In the realm of precision manufacturing, gear CNC Machining customization stands as a cornerstone for industries requiring high-tolerance components. At EMAR, we specialize in delivering tailored CNC solutions that meet the exacting standards of modern engineering applications.

Understanding Gear CNC Machining Customization

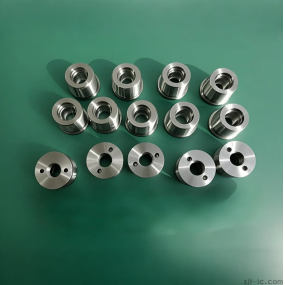

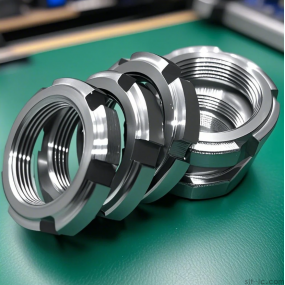

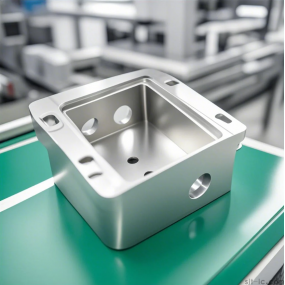

Custom gear machining involves the use of advanced CNC technology to produce gears with specific tooth profiles, dimensions, and material properties. Unlike standard gear production, custom CNC machining allows for:

Precision tolerances within ±.005mm

Complex geometries including helical, bevel, and worm gears

Material versatility from aluminum alloys to titanium

The EMAR Advantage in Gear Manufacturing

Our facility combines 5-axis CNC machining centers with proprietary toolpath optimization to deliver gears with superior surface finishes and extended service life. Key differentiators include:

Dedicated quality control lab with CMM verification

ISO 9001-certified production processes

Prototype-to-mass-production capabilities

Applications Across Industries

From automotive transmissions to aerospace actuators, our CNC gear machining services support critical applications where precision and reliability are non-negotiable. We regularly manufacture components for:

Robotic joint mechanisms

Medical imaging equipment

Renewable energy systems

Discover how EMAR's technical expertise can optimize your gear-driven systems. Visit our website to request a free design consultation and machining quote today.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque