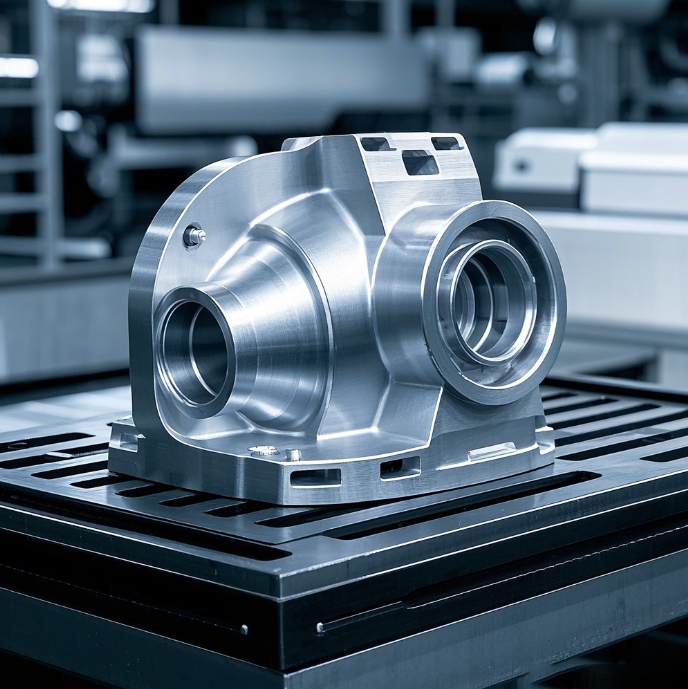

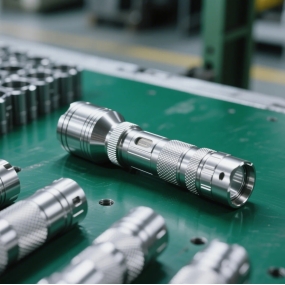

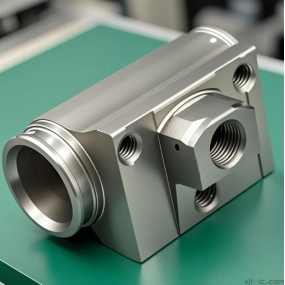

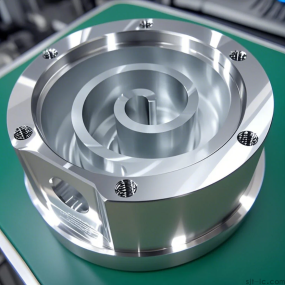

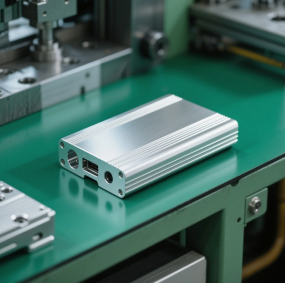

As a leading CNC stainless steel custom machining provider, EMAR delivers precision-engineered solutions for industries requiring high durability, corrosion resistance, and complex geometries. Our advanced CNC technology ensures micron-level accuracy for your most demanding stainless steel components.

Why Choose CNC Machining for Stainless Steel Parts?

Stainless steel's exceptional properties – including strength, hygiene, and aesthetic appeal – make it ideal for aerospace, medical, and food processing applications. However, its hardness and work-hardening characteristics require specialized CNC machining expertise. EMAR's technicians overcome these challenges through:

Optimized toolpath programming to minimize heat buildup

Custom coolant strategies for different stainless grades (304, 316, 17-4PH, etc.)

Rigorous quality control meeting ISO 9001 standards

Our Stainless Steel CNC Machining Capabilities

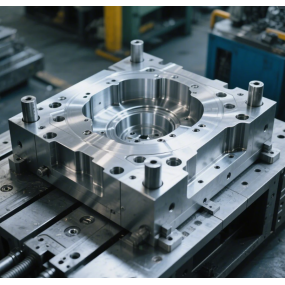

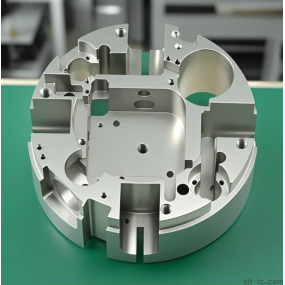

EMAR's 5-axis CNC centers handle all stainless steel machining processes:

Precision milling: ±.005mm tolerance for complex contours

Turning operations: Diameters from 5mm to 500mm

Multi-axis machining: Single-setup completion of intricate parts

Surface finishing: Bead blasting, electropolishing, or mirror polishing

Industry-Specific Solutions

We've successfully delivered custom stainless steel components for:

Medical: Surgical instruments with Ra .2μm surface finish

Semiconductor: Ultra-clean vacuum chamber parts

Marine: Saltwater-resistant fittings and flanges

With rapid prototyping and mass production capabilities, EMAR serves both R&D teams and production departments. Our engineers work closely with clients to optimize designs for manufacturability without compromising functionality.

Request a quote today through our website https://www.sjt-ic.com/ or contact our technical team for design consultation. Experience the EMAR difference in CNC stainless steel machining – where precision meets reliability.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque