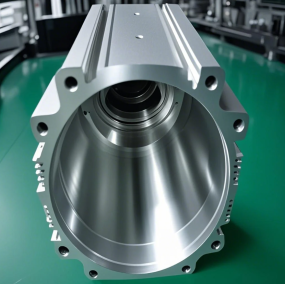

As a leading CNC titanium steel machining specialist, EMAR leverages advanced equipment and 15+ years of metalworking expertise to deliver precision components for aerospace, medical, and industrial sectors. This guide explores the technical nuances of machining this challenging alloy.

Why Choose CNC for Titanium Steel Components?

Titanium steel alloys demand specialized CNC Machining approaches due to their unique properties:

- High strength-to-weight ratio requires rigid machine tools

- Low thermal conductivity necessitates optimized cooling strategies

- Work hardening characteristics demand precise toolpath planning

EMAR's 6-Step Titanium Machining Protocol

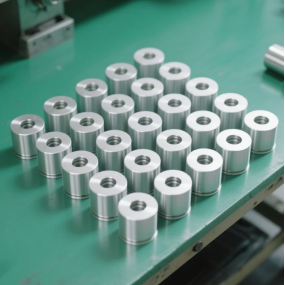

Our certified process ensures dimensional accuracy ±.005mm:

- Material certification (ASTM B348 Grade 5 compliance)

- 5-axis simultaneous machining with high-pressure coolant

- In-process quality verification

- Deburring and edge treatment

- Surface enhancement (bead blasting/anodizing options)

- Final CMM inspection

Industry-Specific Solutions

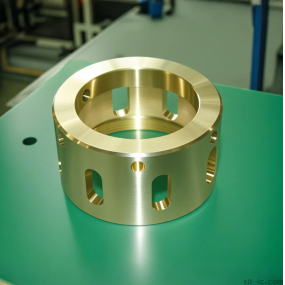

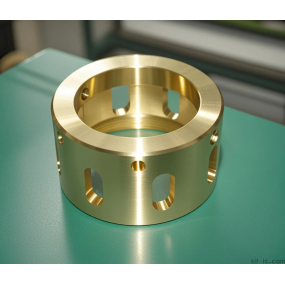

We manufacture mission-critical titanium steel components including:

- Aerospace: Engine mounts, landing gear parts

- Medical: Surgical implants with biocompatible finishes

- Automotive: Lightweight structural components

With ISO 9001:2015 certification and 98.7% on-time delivery rate, EMAR combines technical excellence with reliable supply chain management. Contact our engineering team at www.sjt-ic.com for project-specific machining solutions.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque