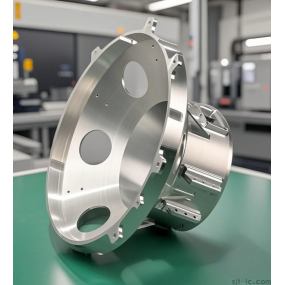

In the rapidly evolving semiconductor industry, precision and reliability are paramount. CNC Machining semiconductor parts requires specialized expertise to meet the exacting standards of this sector. At EMAR, we combine advanced CNC technology with deep material knowledge to deliver components that power cutting-edge electronic devices.

Why Choose CNC Machining for Semiconductor Components?

Semiconductor manufacturing demands parts with micron-level tolerances, exceptional surface finishes, and perfect geometric accuracy. CNC machining offers several advantages for producing these critical components:

Ability to work with specialized materials like aluminum alloys, stainless steel, and engineering plastics

Repeatable precision for high-volume production

Complex geometries achievable in single setups

Superior surface finishes that minimize contamination risks

Key Applications in Semiconductor Equipment

Our CNC machining services support various semiconductor manufacturing processes:

Wafer handling components

Vacuum chamber parts

Precision alignment fixtures

Plasma etch components

Metrology equipment parts

EMAR's Capabilities for Semiconductor Manufacturing

With our state-of-the-art CNC equipment and ISO-certified processes, EMAR delivers:

Tolerances down to ±.005mm

Surface finishes to Ra .2μm

Cleanroom-compatible machining processes

Material traceability and certification

DFM support for optimal part design

Partner with EMAR for Your Semiconductor Needs

As your trusted CNC machining partner, we understand the critical nature of semiconductor components. Our team works closely with clients to ensure parts meet exact specifications while optimizing for manufacturability and cost-efficiency. Contact EMAR today to discuss your semiconductor machining requirements.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque