High-Volume CNC Fastener Machining: Precision and Efficiency for Industrial Applications

In the realm of industrial manufacturing, high-volume CNC fastener machining is a critical process that demands precision, consistency, and scalability. At EMAR, we specialize in delivering top-tier CNC Machining solutions tailored for mass production of fasteners, ensuring your projects meet the highest standards of quality and efficiency.

What is High-Volume CNC Fastener Machining?

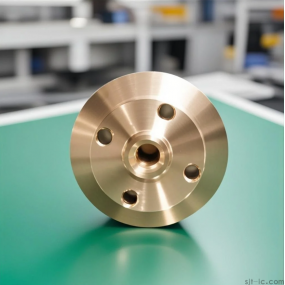

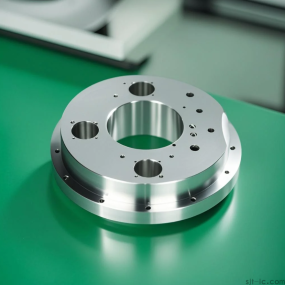

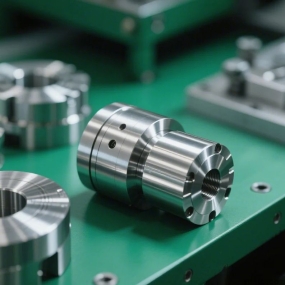

This process involves using computer-controlled machines to produce large quantities of fasteners—such as screws, bolts, and nuts—with exacting tolerances. CNC technology enables rapid, repeatable production while maintaining uniformity across batches, making it ideal for industries like automotive, aerospace, and construction.

Key Advantages of Partnering with EMAR

1. Precision Engineering: Our advanced CNC machines achieve tolerances as tight as ±.005mm, ensuring every fastener meets specifications.

2. Material Versatility: We machine stainless steel, titanium, aluminum, and exotic alloys to suit diverse applications.

3. Scalability: Automated tooling and 24/7 production capabilities support large-scale orders without compromising lead times.

4. Cost Efficiency: Bulk production reduces per-unit costs, offering significant savings for OEMs.

Industries We Serve

From automotive assembly lines to renewable energy infrastructure, our CNC-machined fasteners are trusted for their reliability. We also provide custom threading, surface treatments (e.g., anodizing, plating), and quality certifications (ISO 9001, RoHS) to meet regulatory requirements.

Why Choose EMAR for Your Fastener Needs?

With decades of expertise in CNC machining services, EMAR combines cutting-edge technology with rigorous quality control. Our team collaborates closely with clients to optimize designs for manufacturability, reducing waste and accelerating time-to-market. Visit our website to explore case studies or request a quote today.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque