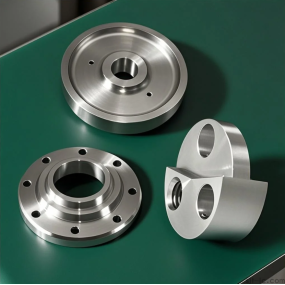

In industrial fluid control systems, CNC Machining valve components plays a critical role in ensuring reliability, durability, and leak-free operation. As a leading CNC machining service provider, EMAR combines advanced technology with aerospace-grade precision to manufacture valve parts that meet stringent industry standards.

Why Choose CNC Machining for Valve Components?

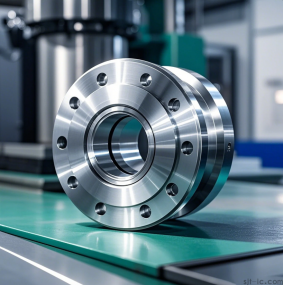

Modern valves demand micron-level accuracy in components like bodies, stems, seats, and flanges. Our 5-axis CNC centers achieve tolerances up to ±.005mm, while automated tool changers enable complex geometries in materials ranging from brass and stainless steel to exotic alloys.

Key Manufacturing Processes

1. Material Selection: We recommend grade 316L stainless steel for corrosive environments or titanium for high-pressure applications

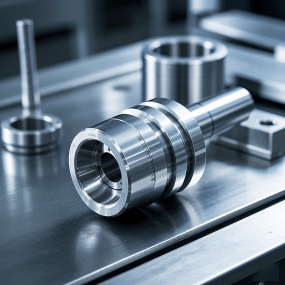

2. Precision Turning: Producing concentric valve stems with surface finishes to Ra .4μm

3. Multi-axis Milling: Creating internal flow channels with computational fluid dynamics optimization

4. Quality Assurance: 100% coordinate measuring machine (CMM) inspection with traceable certifications

EMAR's Technical Advantages

Our CNC machining facility features:

- 18 Swiss-type CNC lathes for small-diameter components

- 7 vertical machining centers with pallet changers

- In-house heat treatment and surface coating capabilities

- AS910D and IATF 16949 certified processes

Industry Applications

We serve:

✔ Oil & gas: API 6A/6D compliant valves

✔ Power generation: Nuclear-grade shutoff valves

✔ Semiconductor: Ultra-high purity gas valves

✔ Automotive: Fuel system components

With 12 years of experience in CNC machining valve components, EMAR delivers:

- 15-30% cost reduction through optimized machining strategies

- 98.7% on-time delivery rate

- Engineering support from prototype to mass production

Visit our website for technical specifications and case studies.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque