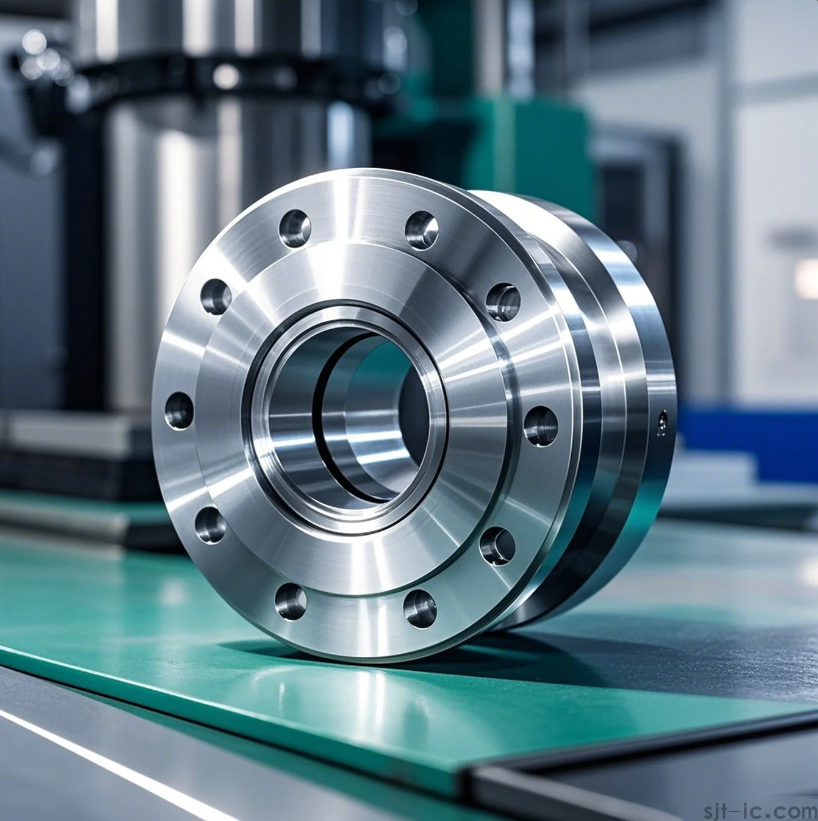

In modern manufacturing, bearing CNC Machining plays a pivotal role in producing high-precision components for automotive, aerospace, and heavy machinery industries. As a leading CNC machining service provider, EMAR specializes in delivering customized bearing solutions with micron-level accuracy.

Why Choose CNC Machining for Bearing Production?

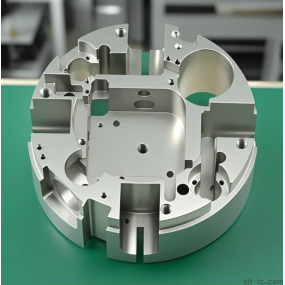

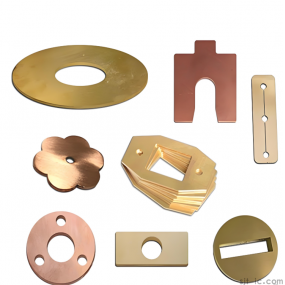

CNC technology enables the creation of bearings with complex geometries, tight tolerances (±.005mm), and superior surface finishes (Ra .4μm). Our 5-axis CNC machines at EMAR can process various bearing materials including:

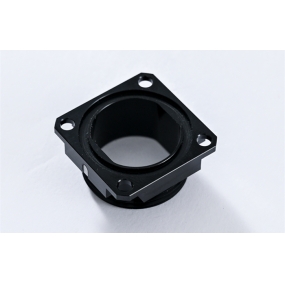

Carbon/alloy steels (GCr15, 52100)

Stainless steels (440C, 304)

Bronze and brass alloys

Engineering plastics (PEEK, PTFE)

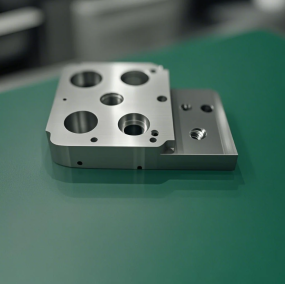

EMAR's Bearing CNC Machining Capabilities

Our facility features advanced CNC turning centers and machining cells specifically configured for bearing manufacturing:

OD/ID grinding for raceways (⌀3-500mm)

Precision boring for housing units

Automated groove cutting for ball/roller paths

Hard turning (HRC 60+) capabilities

Quality Assurance in Every Bearing Component

EMAR implements rigorous quality control measures including CMM inspection (.001mm repeatability), surface roughness testing, and material certification. Our CNC machining processes comply with ISO 9001 and AS910 standards, ensuring bearings meet:

ABEC 7/9 precision grades

DIN 620 specifications

Custom OEM requirements

With 15+ years of experience in precision machining, EMAR provides complete bearing solutions from prototyping to mass production. Contact our engineering team at www.sjt-ic.com for technical consultation and quote requests.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque