As a leading ship parts CNC Machining provider, EMAR specializes in delivering precision-engineered components for marine applications. Our advanced CNC technology ensures compliance with stringent maritime industry standards.

Why Choose CNC Machining for Marine Components?

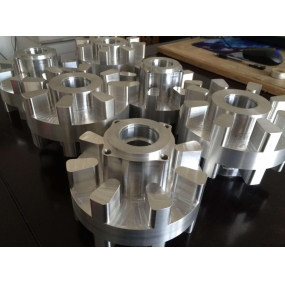

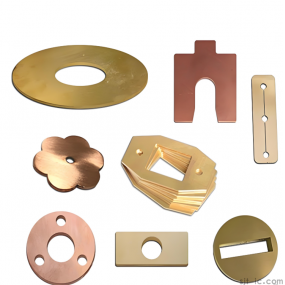

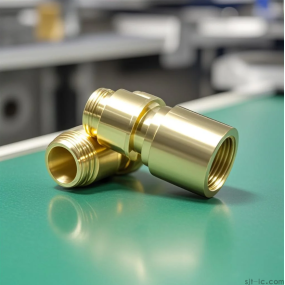

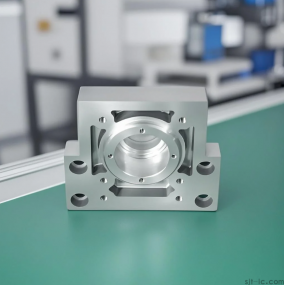

Marine environments demand exceptional corrosion resistance and dimensional stability. Our CNC machining services utilize marine-grade aluminum alloys, stainless steels (316L/2205), and nickel-aluminum bronzes to withstand saltwater exposure while maintaining tight tolerances (±.005mm).

Key Applications in Shipbuilding

We manufacture critical components including:

- Propeller shaft brackets

- Valve bodies and hydraulic manifolds

- Deck machinery parts

- Engine mounting components

EMAR's Technical Advantages

Our 5-axis CNC centers achieve complex geometries required for hydrodynamic efficiency. All ship parts undergo:

1. Salt spray testing (ASTM B117)

2. Ultrasonic thickness measurement

3. Hydrostatic pressure validation

Visit EMAR's official website to request a free DFM analysis for your marine projects.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque