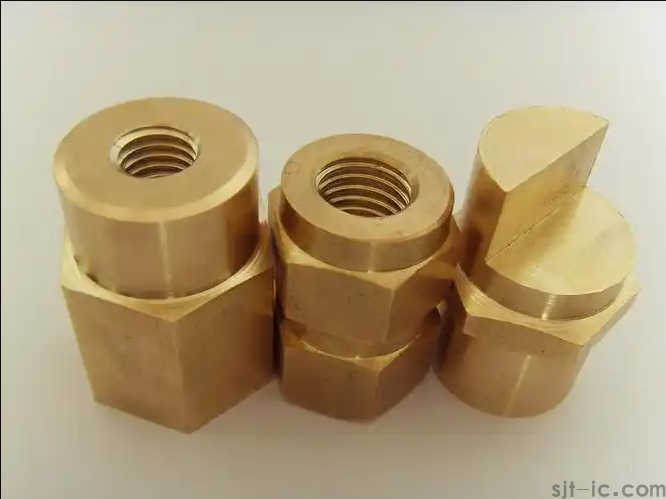

As a leading CNC copper nut processing manufacturer, EMAR specializes in delivering precision-engineered components for industries requiring exceptional durability and conductivity. Our advanced CNC Machining capabilities ensure tight tolerances (±.01mm) and superior surface finishes for copper nuts used in electrical, automotive, and industrial applications.

Why Choose EMAR for CNC Copper Nut Manufacturing?

Our CNC machining facility combines Swiss-type lathes and 5-axis milling systems to produce copper nuts with:

Thread accuracy: Class 4H/6G standards

Material options: C11000, C36000, C54400 alloys

Surface treatments: Anti-oxidation plating, passivation

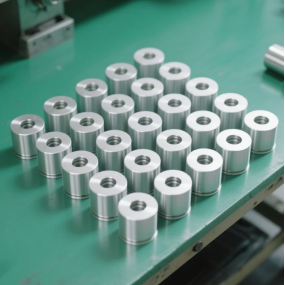

Production capacity: 50,000+ pieces/month

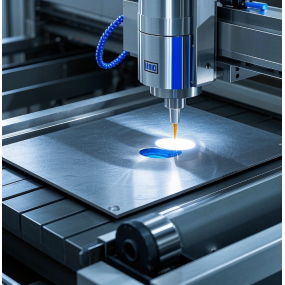

Precision Manufacturing Process

The CNC copper nut processing workflow includes:

Material certification (RoHS/REACH compliant)

CNC turning with live tooling

Thread rolling/whirling

Deburring and ultrasonic cleaning

100% dimensional inspection

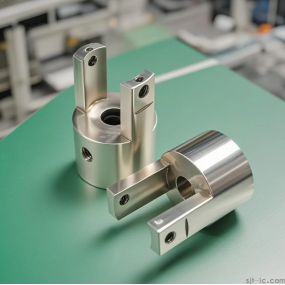

Industry-Specific Solutions

We customize copper nuts for:

Electrical connectors (UL/CE certified)

HVAC compression fittings

Automotive grounding components

Robotic arm assemblies

EMAR's ISO 9001-certified facility guarantees traceability from raw material to finished product. Request instant quoting through our online portal at www.sjt-ic.com, with DFM feedback within 24 hours.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque