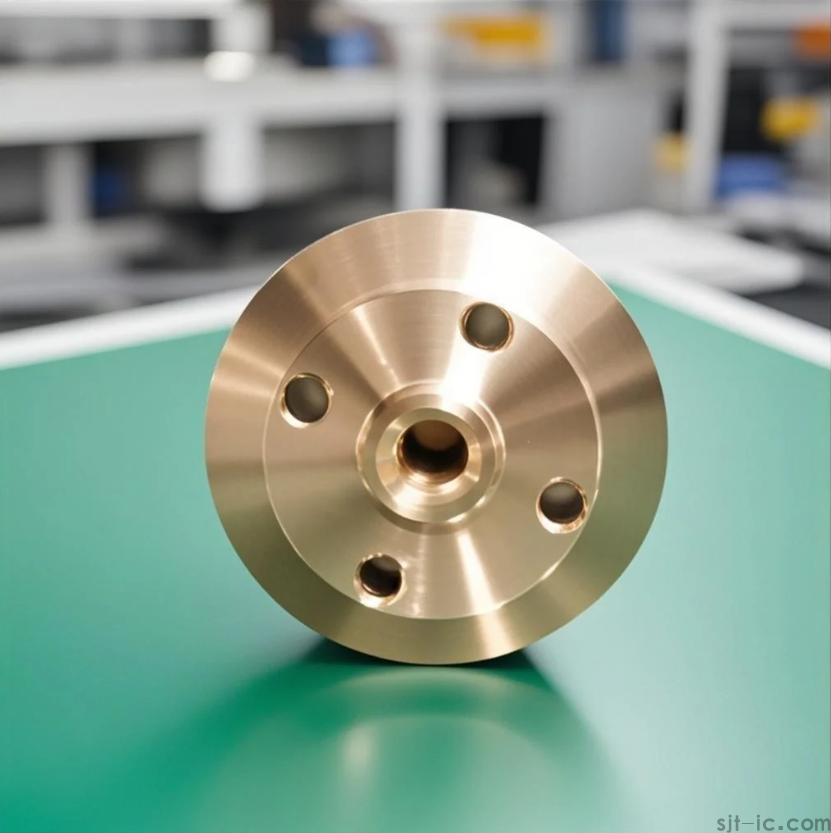

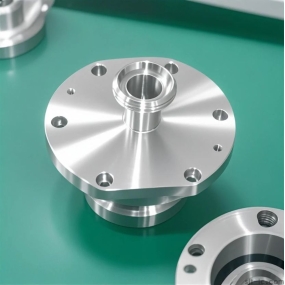

Have you ever wondered 🤔 how those precise and reliable brass fittings are produced? I often work with machining processes, so today let’s talk about CNC Machining of brass fittings—especially why so many precision part machining projects “set their sights” on brass materials?

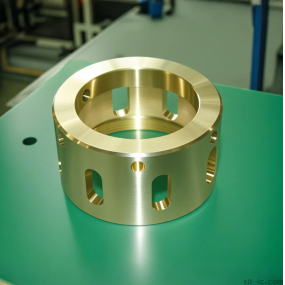

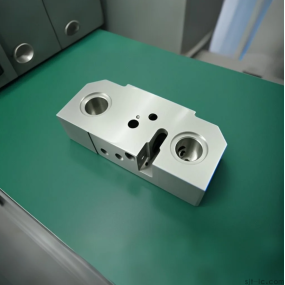

Actually, brass (a copper-zinc alloy) is quite “popular” in CNC machining. It is easy to machine, corrosion-resistant, has good strength and fluidity, making it particularly suitable for turning and milling complex parts. For example, water pipe fittings, electrical terminals, and valve components made via brass CNC machining boast high precision 🛠️ and durability. In my opinion, choosing the right material makes the machining process twice as effective with half the effort.

But with so many types of brass available, how do you choose the right one for machining? Let’s compare several common types in the table below—

| Brass Type | Lead Content | Key Characteristics | Typical Application Scenarios |

|------------|--------------|----------------------|-------------------------------|

| C360 | Relatively High | Extremely easy to machine; excellent surface finish | General-purpose fittings, screws, gear parts |

| C230 | Low | Strong corrosion resistance; good toughness | Plumbing equipment, components for marine environments |

| C220 | Relatively Low | Wear-resistant; excellent electrical conductivity | Electrical connectors, high-friction components |

So you see, different grades of brass have varying properties. C360 is easy to machine but has a slightly higher lead content; C230 offers better corrosion resistance; C220 excels in wear resistance and electrical conductivity. When selecting a material, you need to figure out where your part will be used and what performance requirements it must meet.

Let’s also talk about the machining process itself. Although brass is a “machining-friendly” material, precision control and surface treatment are crucial. Precision must be controlled to ±0.01mm or even stricter, and surface treatments like polishing and electroplating cannot be overlooked—otherwise, the appearance and corrosion resistance may be compromised 💡.

Oh, right! Sometimes small issues may arise during machining, such as faster tool wear (especially with leaded brass) or difficulties in chip control. Fortunately, brass generally offers high machining efficiency and relatively moderate costs.

Finally, I want to explain why some people insist on using brass for precision parts. It’s simply because brass achieves an excellent balance of comprehensive properties—it is not difficult to machine, has good mechanical performance and corrosion resistance, and is recyclable ♻️, which also makes it acceptable in terms of environmental friendliness. For fitting parts that require precision, durability, and frequent exposure to water or corrosive environments, brass is indeed a reliable choice.

Therefore, for CNC machining of brass fittings, choosing the right material and a reputable manufacturer ensures quality. Hope this helps you!

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque