I often receive questions from customers: When using CNC Machining for metal enclosures of security surveillance equipment, how should we choose materials and control precision? Having worked with many relevant cases, I’m sharing my experience today in the hope of helping you! 😊

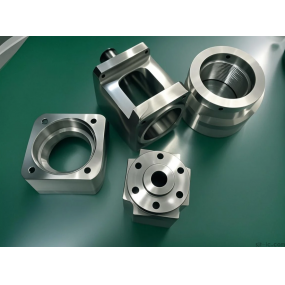

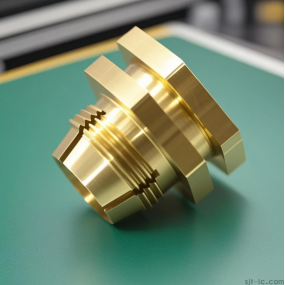

Security equipment is used outdoors year-round, so its enclosure must be **corrosion-resistant and impact-resistant**. CNC machining can handle complex structures, but some people want to balance low costs with high quality—how to achieve this? In fact, choosing the wrong material will lead to a host of problems later. For example, aluminum alloy works well in general environments, but stainless steel or even titanium alloy is necessary for coastal areas or chemical plants. Otherwise, what if the surveillance camera falls off due to rust?

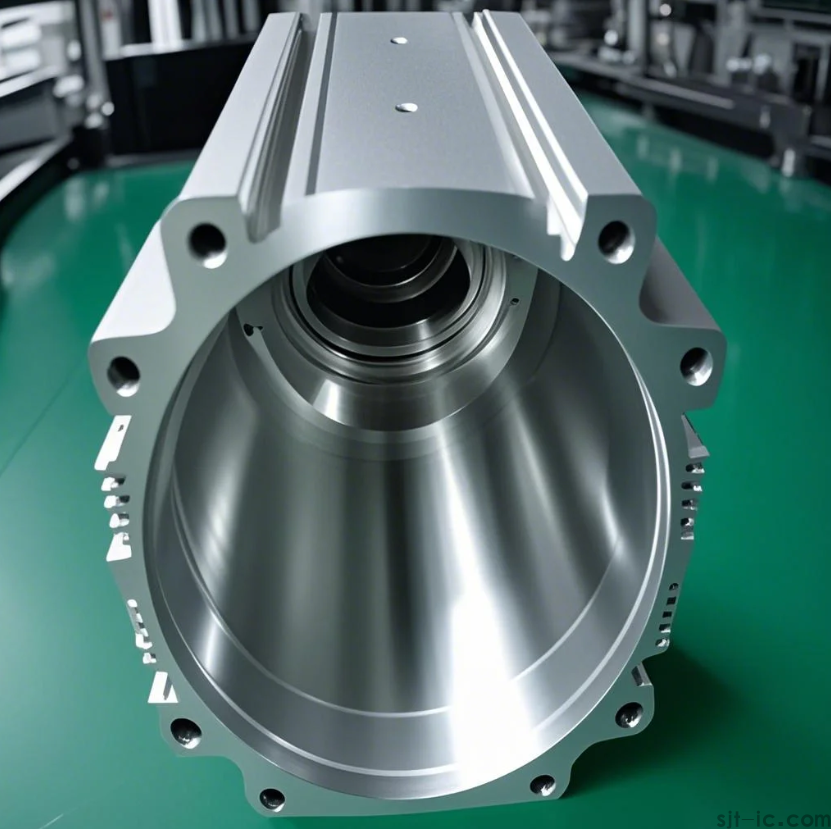

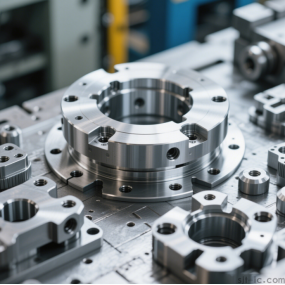

Precision loss is the biggest concern in precision machining! If the hole position deviation of the security enclosure exceeds 0.1mm, it may fail to fit the lens module. I suggest using 5-axis CNC machines for machining—for instance, German equipment can achieve an error of ±0.005mm. Pair it with a coordinate measuring machine (CMM) to check dimensions. Don’t think this step is time-consuming; rework ends up costing much more!

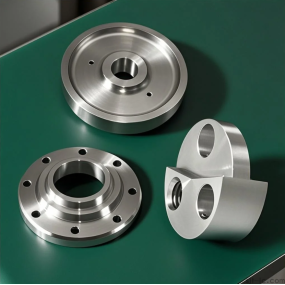

Many people overlook surface treatment! I once saw a factory that skipped anodizing, and as a result, the enclosure wore out and leaked electricity within half a year. 💡 In fact, sandblasting + electroplating can triple wear resistance, and anti-fingerprint treatment prevents marks outdoors—this is crucial for the concealment of surveillance equipment!

Finally, let’s talk about choosing manufacturers: You must check if they have experience in the security industry! Some small factories offer low prices but only handle simple parts; they can’t even mill complex pan-tilt structures accurately. I recommend choosing manufacturers with ISO certification. For example, some enterprises also provide free prototyping—verifying the product before placing a bulk order is much more reliable!

In short, low cost alone isn’t enough for security enclosure machining; material selection, precision control, and surface treatment must be tightly linked. Oh, and don’t forget to ask the manufacturer to conduct a salt spray test for over 96 hours—that’s a mandatory requirement of national standards! 👏

If you need, I can help you make an **English-Chinese comparison table of professional terms for security enclosure CNC machining** (including material names, precision indicators, and testing standards) to make it easier for you to refer to during international communication or document reading.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque