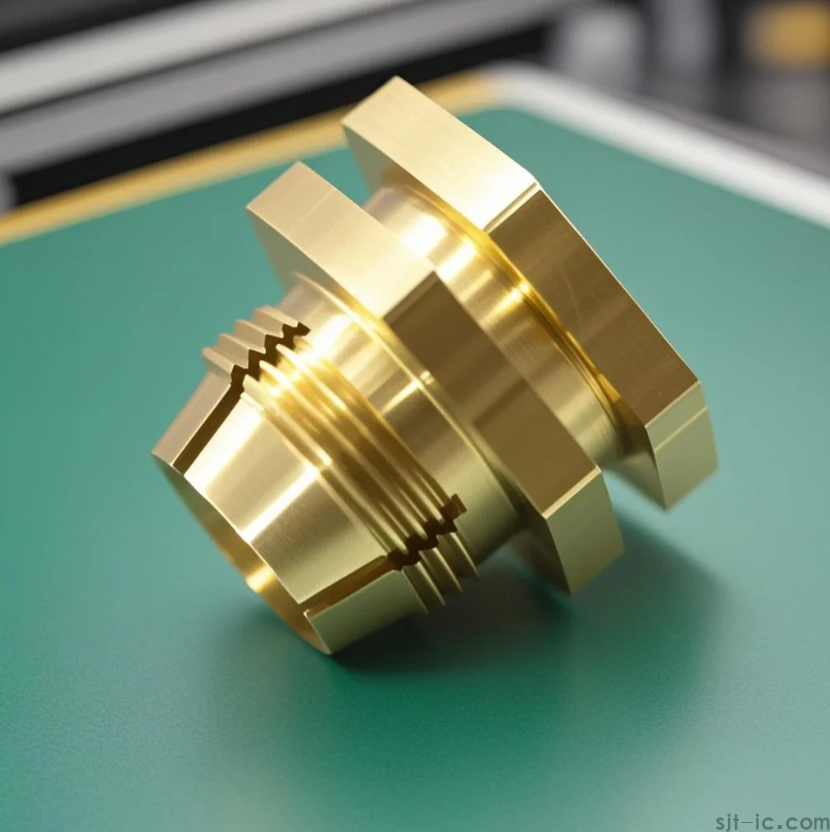

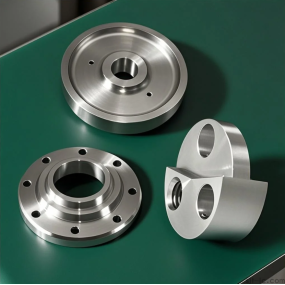

Copper is a critical material in industries requiring high conductivity, corrosion resistance, and thermal efficiency. CNC precision machining copper enables the production of complex components with tight tolerances, making it indispensable for electronics, aerospace, and energy sectors. As a leading CNC Machining manufacturer, EMAR specializes in delivering superior copper parts with unmatched accuracy and surface finish.

Why Choose CNC Machining for Copper Components?

Copper’s softness and high thermal conductivity pose unique challenges in machining. Our advanced CNC systems at EMAR address these with:

High-speed spindles (up to 30,000 RPM) to prevent material deformation

Micro-lubrication systems to manage heat dissipation

4/5-axis capabilities for intricate geometries like heat sinks and busbars

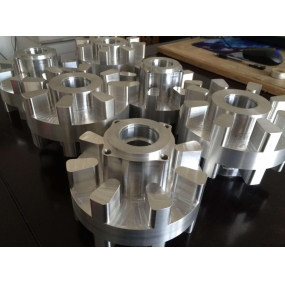

Key Applications of Precision Machined Copper Parts

EMAR’s CNC copper machining serves industries requiring:

Electronics: RF shielding, connectors, and circuit board components

Energy: Wind turbine slip rings, solar panel conductors

Automotive: EV battery cooling plates and charging interfaces

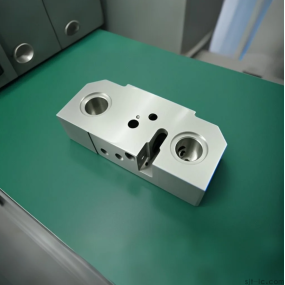

EMAR’s Quality Assurance Process

We implement rigorous quality controls including:

Real-time tool wear monitoring with IoT-enabled machines

Coordinate measuring machines (CMM) for ±.005mm tolerance verification

Surface roughness testing to ensure Ra ≤ .8μm for electrical contacts

With ISO 9001-certified processes and proprietary toolpath optimization software, EMAR delivers copper components with 99.98% on-time delivery. Contact our engineering team for DFM analysis and prototyping services.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque