As a leading CNC Machining service provider, EMAR Company understands that accurate prototype quotation is crucial for our clients' project planning and budgeting. This guide will explain how we calculate CNC machining prototype costs and what factors influence the final price.

Factors Affecting CNC Machining Prototype Costs

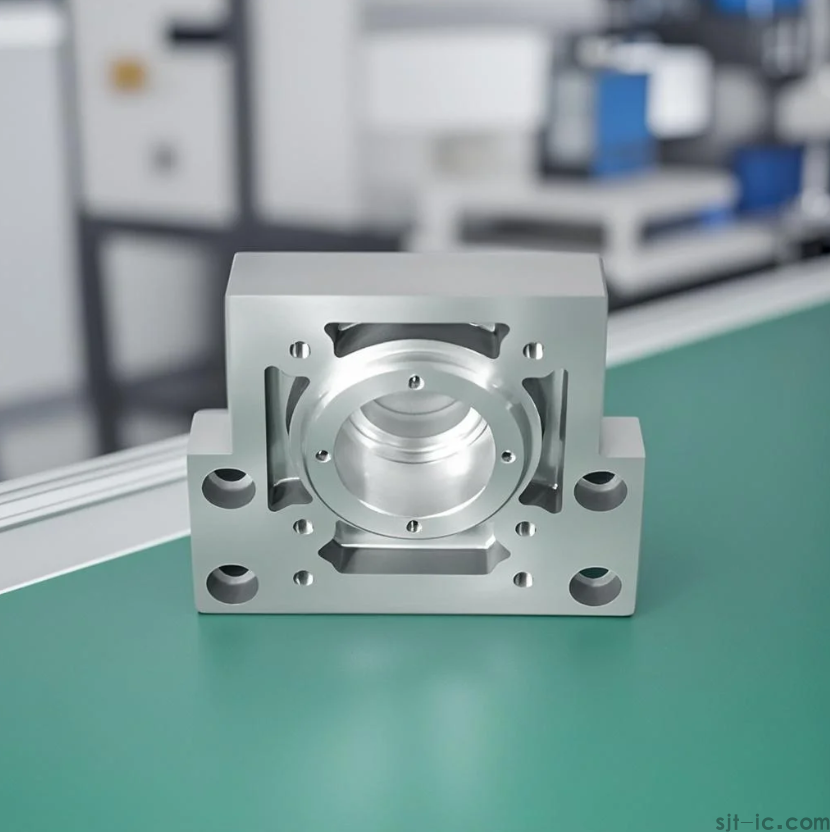

The CNC machining prototype quotation depends on several key elements: material selection, part complexity, required precision, surface finishing, and order quantity. Our engineers evaluate each project individually to provide the most cost-effective solution.

Our Transparent Pricing Structure

At EMAR, we break down our quotation into clear components: material costs (aluminum, steel, titanium, etc.), machining hours, tooling requirements, and any special processing like anodizing or heat treatment. This transparency helps clients understand exactly what they're paying for.

How to Get Your Custom Quote

Simply upload your CAD files to our website (https://www.sjt-ic.com/) or contact our technical team. We typically provide quotations within 24 hours, including DFM (Design for Manufacturing) suggestions to optimize your design for cost-efficiency without compromising quality.

Why Choose EMAR for CNC Prototyping

With 15+ years of experience in precision CNC machining, we offer competitive pricing without sacrificing quality. Our ISO-certified facility in China combines advanced German and Japanese CNC equipment with skilled technicians to deliver prototypes that meet international standards.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque