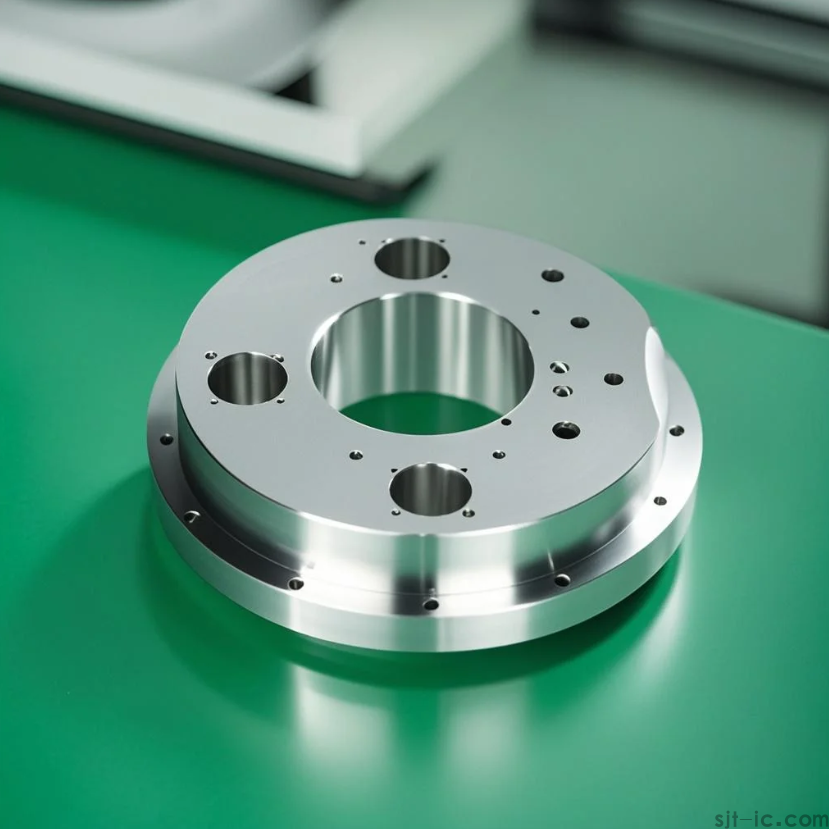

As a leading CNC Machining service provider, EMAR Technology specializes in manufacturing high-precision components for various industries. This article will explore the complete process of precision parts production using advanced CNC technology.

Understanding CNC Machining for Precision Components

CNC (Computer Numerical Control) machining has revolutionized the manufacturing of precision parts by combining automated operations with extreme accuracy. Our CNC machining process begins with comprehensive design analysis to ensure all dimensional tolerances and surface finish requirements are met.

Key Stages in Precision Parts Manufacturing

The production of CNC precision parts involves several critical phases:

1. Material Selection: Choosing the right metal or plastic based on application requirements

2. CAD/CAM Programming: Converting designs into machine-readable instructions

3. Precision Machining: Executing operations like milling, turning, and drilling with micron-level accuracy

4. Quality Inspection: Verifying dimensions using CMM and other advanced metrology equipment

EMAR's Advantages in Precision CNC Machining

Our facility stands out through:

- 50+ advanced CNC machines with 5-axis capabilities

- ISO 9001 certified quality management system

- Experienced engineering team with 15+ years industry knowledge

- Quick-turn prototyping and mass production services

Applications of CNC Machined Precision Parts

Our components serve critical functions in:

• Aerospace and defense systems

• Medical device manufacturing

• Automotive and transportation

• Industrial automation equipment

For your precision machining needs, visit EMAR Technology to request a quote or discuss your project requirements with our technical experts.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque