As a professional CNC Machining service provider, EMAR specializes in manufacturing high-precision metal parts for various industries, including custom metal lighting fixture components. Our advanced CNC technology ensures exceptional quality and consistency for both functional and decorative elements in lighting systems.

Why Choose CNC Machining for Lighting Fixtures?

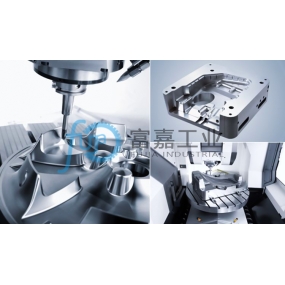

Modern lighting designs increasingly demand complex geometries and tight tolerances that only CNC machining can deliver. Our 5-axis CNC mills and lathes can create intricate patterns, precise mounting interfaces, and flawless surface finishes required for high-end lighting applications.

Materials We Process

We work with various metals suitable for lighting fixtures:

- Aluminum alloys (lightweight and corrosion-resistant)

- Brass (for premium decorative elements)

- Stainless steel (for structural components)

- Copper (for thermal management and aesthetic appeal)

Our Manufacturing Capabilities

EMAR's facility features:

- ±.005mm machining tolerance

- Mirror finishing and various surface treatments

- Prototype to mass production services

- DFM (Design for Manufacturing) consultation

Quality Assurance

Every metal lighting fixture component undergoes rigorous inspection including CMM measurement and visual inspection to ensure perfect fit and finish. Our ISO 9001 certified processes guarantee consistent quality across all production batches.

For your next lighting project requiring precision metal parts, contact EMAR at www.sjt-ic.com to discuss your specific requirements and receive a competitive quote.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque