As a leading CNC Machining service provider, EMAR specializes in manufacturing high-precision aircraft components that meet stringent aerospace standards. Our advanced CNC technology ensures exceptional accuracy and repeatability for critical aerospace applications.

Why Choose CNC Machining for Aircraft Components?

Aerospace components demand extreme precision and reliability. CNC machining offers unparalleled dimensional accuracy (typically within ±.0002 inches) and surface finish quality, making it ideal for aircraft parts like turbine blades, landing gear components, and structural elements.

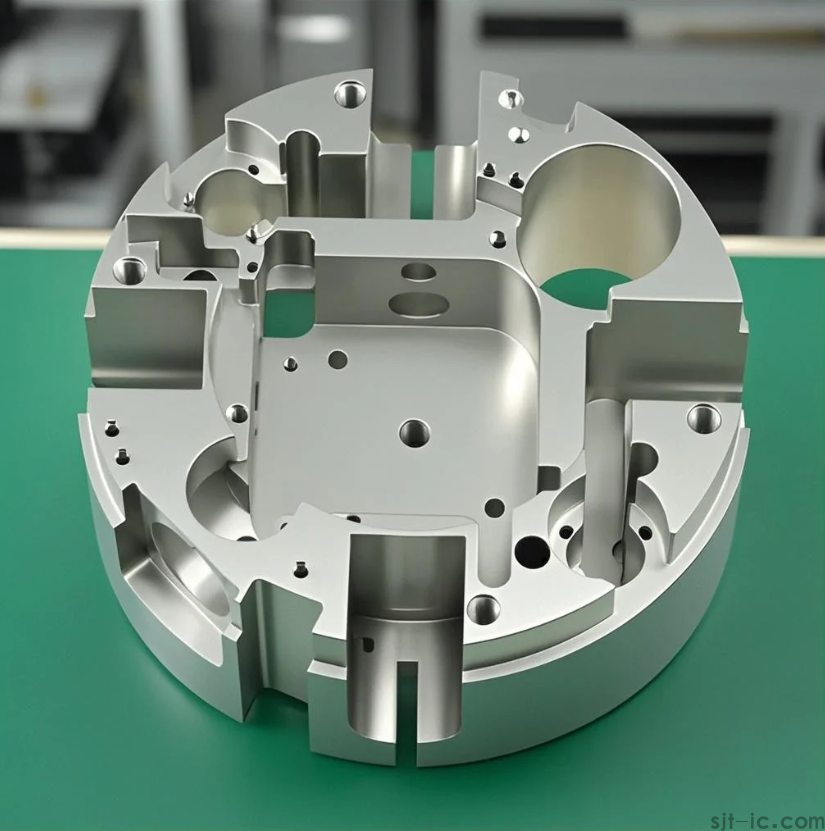

Our Aerospace CNC Machining Capabilities

EMAR's 5-axis CNC machines can handle complex geometries in materials including titanium, aluminum alloys, and high-temperature superalloys. We maintain AS910D certification and implement rigorous quality control processes to ensure every component meets aviation safety requirements.

Material Expertise for Aerospace Applications

We machine all aerospace-grade materials:

- Titanium (Grade 5, Grade 23)

- Aluminum (2024, 6061, 7075)

- Stainless steels (15-5PH, 17-4PH)

- Nickel-based superalloys (Inconel, Hastelloy)

Our engineers optimize tool paths and cutting parameters to prevent material stress and maintain metallurgical properties critical for aircraft component performance.

Quality Assurance and Certification

EMAR provides complete documentation including material certifications, first article inspection reports (FAIR), and full traceability. Our quality management system complies with AS910D, ISO 9001, and NADCAP standards for aerospace manufacturing.

Why Partner with EMAR for Your Aircraft Components?

With 15+ years of aerospace machining experience, EMAR delivers:

- Short lead times (as fast as 72 hours for prototype parts)

- Competitive pricing without compromising quality

- Engineering support from design to production

- Strict confidentiality for proprietary designs

Contact our aerospace machining specialists today to discuss your project requirements and receive a free DFM analysis.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque