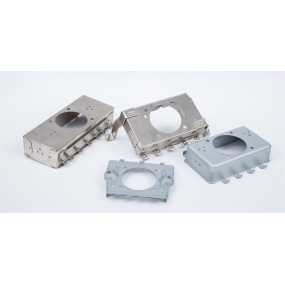

As a leading CNC Machining service provider, EMAR specializes in precision brass components manufacturing. This article will explore the technical nuances of brass machining to help procurement managers and engineers make informed decisions.

Understanding CNC Brass Machining

CNC brass machining refers to the computer-controlled subtractive manufacturing process for creating brass parts with tight tolerances (typically ±.005mm). Brass alloys like C36000 (free-cutting brass) are preferred for their excellent machinability rating of 100% (compared to steel's 60%).

Key Process Stages

1. Material Selection: We use certified brass rods/billets with Cu content 60-63% and Zn 35-40% for optimal machinability and corrosion resistance.

2. CNC Programming: Our engineers develop toolpaths considering brass's softness (HB80-100) to prevent material adhesion.

3. Machining Operations: Combining turning (surface speeds 150-300m/min) and milling (feed rates .05-.15mm/tooth) for complex geometries.

4. Quality Control: CMM inspection with 3μm repeatability ensures dimensional accuracy.

EMAR's Technical Advantages

- 15+ years brass machining experience

- 50+ CNC machines (including 5-axis simultaneous machining centers)

- Surface roughness Ra .8μm achievable

- ISO 9001:2015 certified quality system

For precision brass components that demand exceptional quality and reliability, contact EMAR's engineering team for customized solutions.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque