When sourcing CNC Machining aluminum parts, selecting the right manufacturer is critical for quality, precision, and cost-effectiveness. As an ISO-certified CNC machining specialist, EMAR offers comprehensive solutions for aluminum components across industries.

Key Selection Criteria for Aluminum CNC Machining

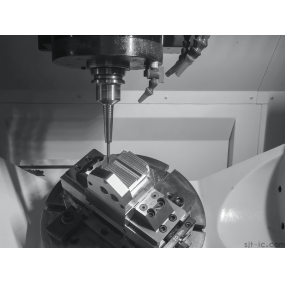

1. Precision Capabilities: Our 5-axis CNC machines achieve ±.005mm tolerances

2. Material Expertise: Processing 6061, 7075, and other aerospace-grade alloys

3. Surface Finishing: Anodizing, powder coating, and chemical conversion coatings

4. Quality Assurance: Full-spectrum inspection with CMM and optical comparators

Why EMAR Stands Out in Aluminum CNC Machining

• 15+ years of CNC machining experience with 200+ successful projects

• Proprietary toolpath optimization for aluminum-specific machining

• Just-in-time production with 98% on-time delivery rate

• Competitive pricing through lean manufacturing processes

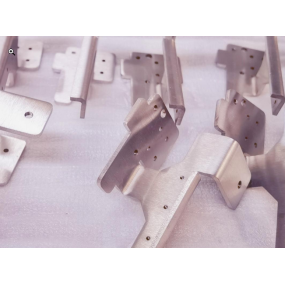

Applications of Our CNC Machined Aluminum Parts

From automotive components to medical device enclosures, our aluminum machining services support:

- Lightweight structural frames

- Heat-sensitive electronic housings

- High-strength aerospace brackets

- Custom prototype development

Visit EMAR's official website to request a free DFM analysis and instant quotation for your aluminum CNC machining project.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque