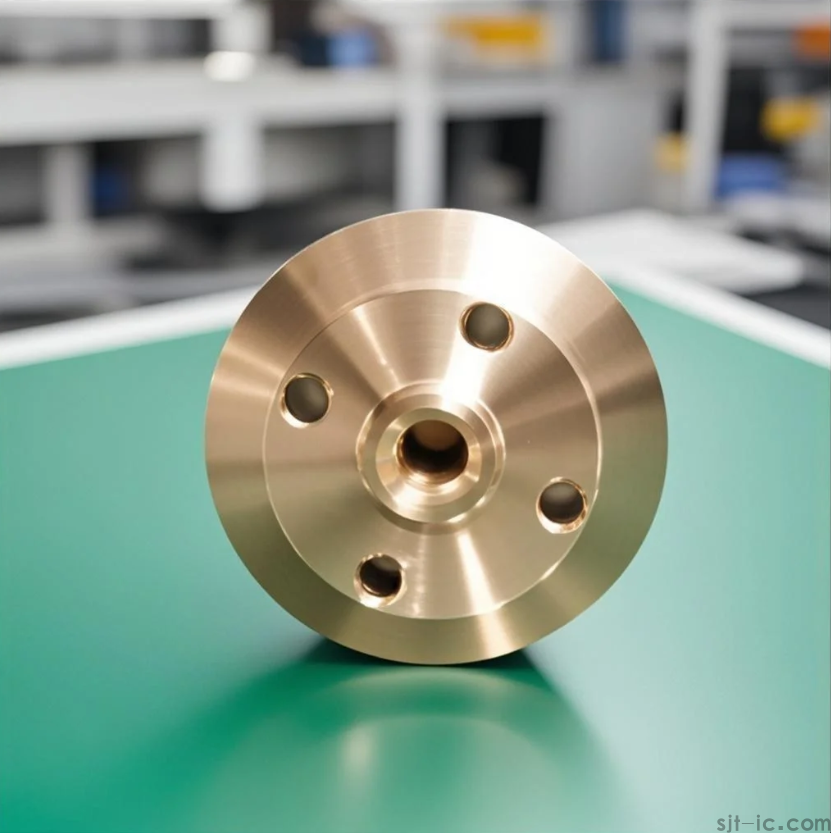

As a leading CNC Machining service provider, EMAR specializes in precision copper parts manufacturing with strict quality control and efficient production processes.

Understanding CNC Machining for Copper Parts

Copper is widely used in electrical components, heat exchangers, and precision instruments due to its excellent conductivity and thermal properties. The CNC machining copper parts process requires specific considerations to achieve optimal results while maintaining material integrity.

Key Steps in CNC Copper Machining

1. Material Selection: Choose the right copper alloy (C10100, C11000, etc.) based on application requirements.

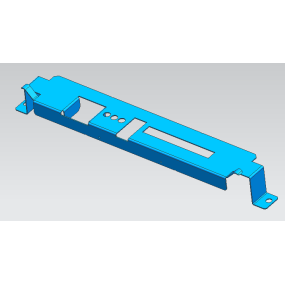

2. CAD Design: Create precise 3D models with tolerance specifications.

3. Toolpath Programming: Optimize cutting paths for copper's unique properties.

4. Machining Process: Implement appropriate cutting speeds and coolants.

5. Quality Inspection: Verify dimensions and surface finish.

Technical Advantages of EMAR's CNC Copper Machining

Our CNC machining capabilities for copper parts include:

±.005mm dimensional accuracy

Surface roughness Ra .4μm achievable

Deburring and surface treatment options

Batch production consistency

Why Choose EMAR for Your Copper Parts

With advanced 5-axis CNC machines and experienced technicians, we deliver:

Precision: Tight tolerance control for critical applications

Efficiency: Optimized production workflow

Quality Assurance: Full inspection reports provided

Custom Solutions: From prototyping to mass production

Contact EMAR today at www.sjt-ic.com for your precision copper machining needs. Our engineering team is ready to provide technical support and competitive quotations.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque