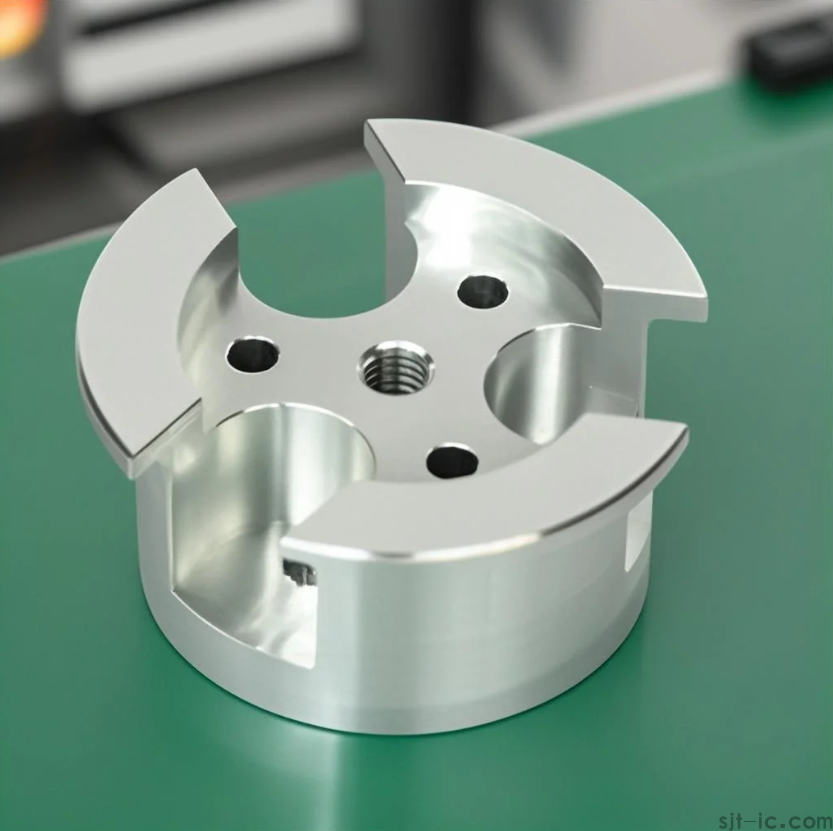

As a professional CNC Machining service provider, EMAR understands that CNC machining costs are a top concern for procurement managers and engineers. This article explores practical strategies to balance budget and precision while highlighting our technical advantages at EMAR.

Understanding CNC Machining Cost Components

The total CNC machining fee comprises material selection, machine time, labor expertise, and post-processing. At EMAR, we optimize each element through:

- AI-powered toolpath optimization reducing machine hours by 15-30%

- Bulk material procurement partnerships

- Multi-axis simultaneous machining minimizing secondary operations

3 Proven Strategies to Reduce Your CNC Expenses

1. Design for Manufacturability (DFM): Our engineers provide free DFM analysis to eliminate unnecessary complex features

2. Batch Ordering: Consolidated production runs achieve economies of scale

3. Material Alternatives: We recommend cost-effective substitutes without sacrificing performance

Why EMAR Delivers Superior Cost-Performance Ratio

With 12+ years in precision machining, we combine German-engineered equipment (DMG MORI, Mazak) with ISO 9001-certified processes to ensure every dollar spent on CNC machining services yields maximum value. Our transparent quoting system breaks down all cost factors for informed decision-making.

Request a project-specific cost analysis today at www.sjt-ic.com and discover how EMAR makes precision machining affordable.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque