What Makes a Reliable CNC Aluminum Parts Manufacturer?

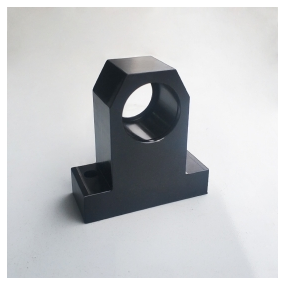

When searching for "CNC aluminum parts manufacturer", key factors include machining precision (typically ±.01mm), material certification (like ISO 9001), and production capacity. EMAR CNC Machining center maintains 50+ CNC machines with 5-axis capabilities, specializing in aerospace-grade 6061/7075 aluminum alloys with surface roughness Ra .8μm.

Critical Evaluation Criteria

1. Technical Capabilities: Verify machine types (3/4/5-axis), maximum workpiece dimensions, and precision tolerances

2. Quality Systems: Require ISO 9001 certification and material traceability documentation

3. Production Efficiency: Evaluate lead times (standard: 5-7 days for prototypes, 15 days for batch production)

4. Testing Equipment: Essential CMM (Coordinate Measuring Machine) verification for critical dimensions

Why EMAR Stands Out in CNC Aluminum Machining

Our Shenzhen facility features:

• 15,000㎡ workshop with temperature/humidity control

• 12 Swiss-made CNC machining centers achieving ±.005mm tolerance

• Dedicated aluminum machining cell with high-pressure coolant systems

• Complete post-processing: anodizing (MIL-A-8625), sandblasting, laser engraving

For complex aluminum components requiring tight tolerances , request our DFM (Design for Manufacturing) analysis service to optimize your designs for cost-effective production.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque