When searching for "Which is the best for CNC precision machining", EMAR stands out as a premier provider of precision CNC Machining services with 15+ years of industry expertise. This article will guide you through key selection criteria and showcase why our Shenzhen-based facility is the optimal choice for your Precision Machining needs.

How to Evaluate a Quality CNC Precision Machining Provider

Three critical factors determine excellence in CNC Precision Machining:

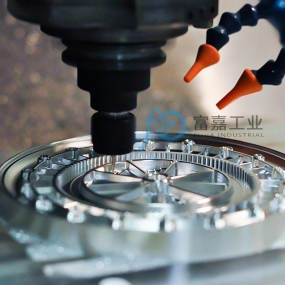

- Equipment Capabilities: EMAR operates 42 advanced CNC centers (5-axis to Swiss-type) with ±.005mm tolerance

- Material Expertise: Specialized machining for aerospace aluminum, medical-grade titanium, and engineering plastics

- Certifications: ISO 9001:2015 certified with IATF 16949 automotive standards compliance

EMAR's Competitive Advantages in Precision Machining

Our CNC Precision Machining services deliver unmatched value through:

- Engineering Support: DFM analysis included with every quotation

- Rapid Prototyping: 3-5 day turnaround for complex parts

- Supply Chain Integration: One-stop solution from machining to surface treatment

Industry-Specific Precision Machining Solutions

We serve specialized sectors with tailored approaches:

- Medical: Mirror-finish surgical components with cleanroom packaging

- Automotive: High-volume production with PPM<50 quality guarantee

- Electronics: Micro-machining for connectors and heat sinks

Visit EMAR's official website to request your free project evaluation. Our engineering team provides technical consultations within 4 business hours, ensuring your Precision Machining requirements are met with optimal solutions.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque