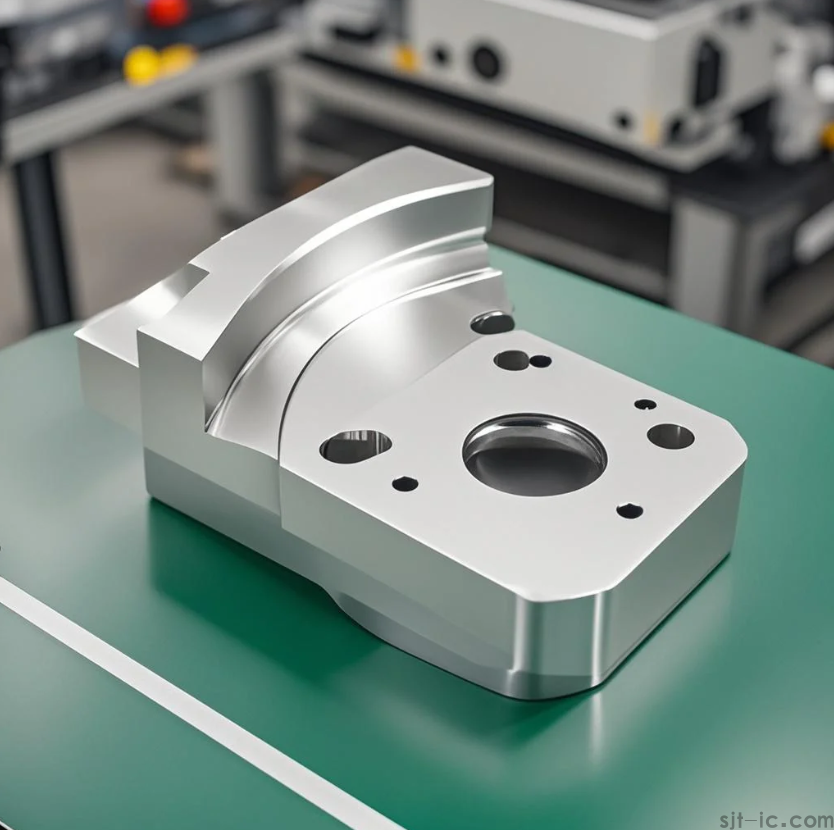

Choosing the right CNC Machining parts factory is critical for manufacturing precision components with consistent quality. As a leading CNC Parts Processing Factory, EMAR combines advanced technology with rigorous quality control to deliver exceptional machining solutions.

Key Selection Criteria for CNC Machining Factories

When evaluating "Which is a good CNC parts processing factory", consider these essential factors:

- ISO 9001 certified quality management systems

- Multi-axis CNC machining capabilities (3/4/5-axis)

- Material expertise (aluminum, steel, titanium, plastics)

- Precision tolerance standards (typically ±.01mm)

- Batch production capacity and lead time reliability

EMAR's Competitive Advantages

Our Shenzhen-based facility stands out through:

- 30+ high-precision CNC machining centers

- DFM (Design for Manufacturing) engineering support

- Strict first-article inspection process

- Flexible prototyping to mass production services

- Competitive pricing with traceable quality

Industry-Specific Solutions

We specialize in precision components for:

- Automotive and aerospace applications

- Medical equipment manufacturing

- Electronics enclosure and heat sinks

- Industrial automation parts

Quality Assurance Process

EMAR implements comprehensive quality control including CMM measurement, surface roughness testing, and material certification to ensure every batch meets international standards.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque