As a leading CNC automotive parts machining supplier, EMAR specializes in delivering precision-engineered components for the automotive industry. Our advanced CNC Machining capabilities ensure exceptional quality, tight tolerances, and reliable performance for critical vehicle applications.

Why Choose EMAR as Your CNC Automotive Parts Supplier?

With ISO 9001-certified production facilities and 15+ years of industry experience, we offer:

- High-precision machining of engine components, transmission parts, and chassis systems

- Material expertise in aluminum alloys, stainless steel, and engineering plastics

- Full-service solutions from prototyping to mass production

- Strict quality control with CMM inspection and surface roughness testing

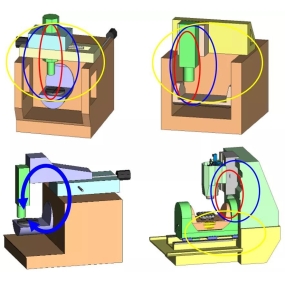

Our CNC Machining Process for Automotive Parts

The CNC machining process begins with CAD/CAM programming to optimize tool paths for complex geometries. Our 5-axis CNC centers then execute precision milling, turning, and drilling operations, achieving tolerances as tight as ±.005mm. Post-machining treatments like anodizing or heat treatment are applied when required.

Industry Applications

We serve:

- Electric vehicle manufacturers (battery housings, motor components)

- Traditional automotive suppliers (fuel system parts, suspension components)

- Aftermarket parts producers (performance upgrades, replacement parts)

As your trusted automotive parts supplier, EMAR combines German-engineered CNC equipment with Chinese manufacturing efficiency. Our technical team provides DFM analysis to optimize your designs for manufacturability and cost-effectiveness.

Quality Assurance Commitment

Every component undergoes rigorous inspection including:

- First-article inspection reports (FAIR)

- Statistical process control (SPC) monitoring

- 100% dimensional verification for critical features

Contact our engineering team today to discuss your project requirements and receive a competitive quote within 24 hours.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque