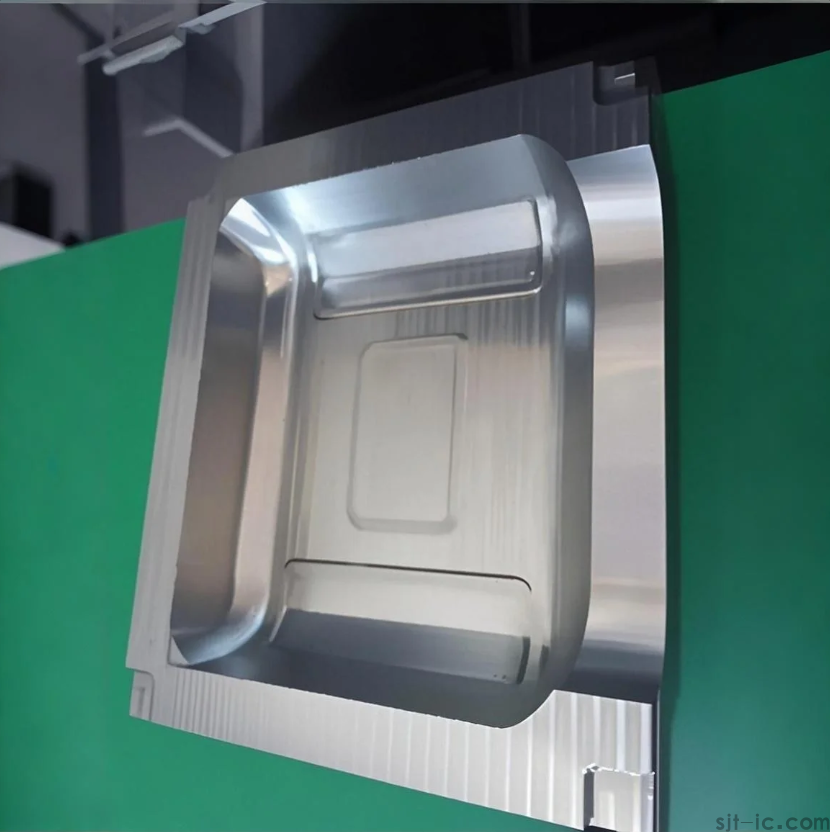

As a professional CNC Machining service provider, EMAR Company specializes in delivering high-precision molds with exceptional surface quality. This article explores the critical techniques for achieving mirror-like finishes in CNC mold machining, addressing a key concern for procurement managers and engineers.

1. Material Selection for Optimal Surface Finish

The foundation of smooth mold surfaces begins with proper material selection. For aluminum molds (e.g., 6061, 7075), we recommend using micro-grain carbide tools with polished flutes. When machining hardened steel (H13, P20), diamond-coated end mills combined with cryogenic cooling yield superior results. Our engineers at EMAR always conduct material analysis before machining to determine the optimal approach.

2. Precision Toolpath Strategies

Our CNC machining process implements advanced toolpath strategies including:

- Contour parallel finishing with stepover ≤5% of tool diameter

- Trochoidal milling for hard materials

- Adaptive clearing to maintain consistent chip load

3. Cutting Parameters Optimization

The perfect balance of spindle speed (15,000-30,000 RPM for aluminum), feed rate (.05-.15mm/tooth), and depth of cut (≤.2mm for finishing) is crucial. EMAR's CNC technicians adjust these parameters in real-time using advanced monitoring systems.

4. Post-Processing Techniques

For ultra-smooth surfaces (Ra<.2μm), we employ:

- Micro-abrasive flow machining

- Electrolytic polishing

- Laser surface texturing (when specified)

At EMAR, we combine these technical approaches with rigorous quality control measures, including white light interferometry for surface roughness verification. Our ISO 9001-certified CNC machining facility ensures consistent results for mold applications across automotive, medical, and consumer electronics industries.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque