Understanding CNC Copper Material Machining

CNC copper material machining is a specialized manufacturing process that requires precision and expertise. As copper possesses unique properties like excellent electrical conductivity, thermal conductivity, and malleability, it demands specific machining techniques to achieve optimal results. At EMAR, we've mastered the art of machining copper components with tight tolerances and superior surface finishes.

Key Challenges in Copper Machining

Machining copper presents several technical challenges that require careful consideration. The material's softness can lead to built-up edge formation, while its high thermal conductivity quickly dissipates heat away from the cutting zone. Our CNC copper machining process addresses these issues through:

- Specialized tool geometries to prevent material adhesion

- Optimized cutting parameters for heat management

- Advanced coolant strategies to maintain dimensional stability

- Precision fixturing to prevent workpiece deformation

Our Advanced CNC Machining Capabilities for Copper

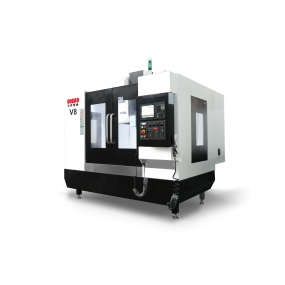

EMAR's state-of-the-art CNC machining centers are specifically configured for copper material processing. We employ:

- High-speed machining for improved surface finishes

- Micro-machining capabilities for intricate copper components

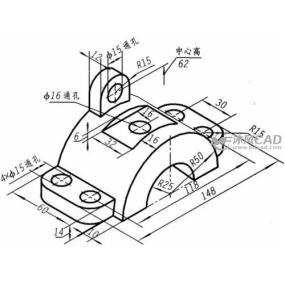

- Multi-axis machining for complex geometries

- In-process inspection systems for quality assurance

Applications of CNC Machined Copper Parts

Our precision-machined copper components serve critical functions across various industries, including electrical connectors, heat exchangers, RF shielding components, and busbars for power distribution systems. The superior conductivity and thermal properties of copper make it indispensable in these applications.

Why Choose EMAR for Your Copper Machining Needs

With years of experience in CNC machining, EMAR offers unparalleled expertise in copper material processing. Our commitment to quality, combined with advanced manufacturing technologies, ensures that every copper component meets the highest industry standards. From prototype development to high-volume production, we deliver precision, reliability, and exceptional value.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque