As a leading CNC Machining service provider, EMAR specializes in precision manufacturing of iron components for industrial applications. This article explores the technical aspects of CNC iron parts machining to help procurement professionals and engineers make informed decisions.

Understanding CNC Machining for Iron Components

Iron parts require specialized CNC machining processes due to their unique material properties. Our ISO-certified facility utilizes advanced 5-axis CNC machines to handle everything from gray iron to ductile iron with micron-level precision.

Key Stages in Our Iron Machining Process

1. Material Selection: We source high-grade iron alloys matched to your application requirements

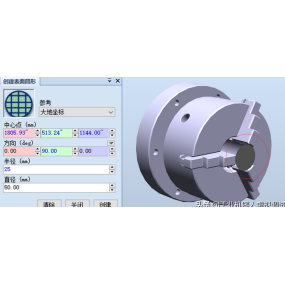

2. Precision Programming: CAD/CAM optimization for complex geometries

3. Machining Operations: Turning, milling, drilling, and threading with rigid tooling

4. Quality Control: CMM inspection and surface finish verification

Why Choose EMAR for Your Iron Parts?

• ±.005mm machining tolerance capability

• Dedicated machining solutions for automotive, hydraulic, and industrial applications

• Complete secondary services including heat treatment and coating

• 24/7 production monitoring with IoT-enabled equipment

Visit EMAR's official website to request a free project evaluation from our engineering team.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque